PHOTO/PIXABAY.

Airplanes are behemoths of the sky; a commercial airliner is over 6,000 times as heavy as a large Canadian goose. At 500 mph, however, these behemoths are not impervious to impact, even from the seemingly innocuous goose. Such damage can result in a range of issues, from fluctuations in air pressure and altitude.

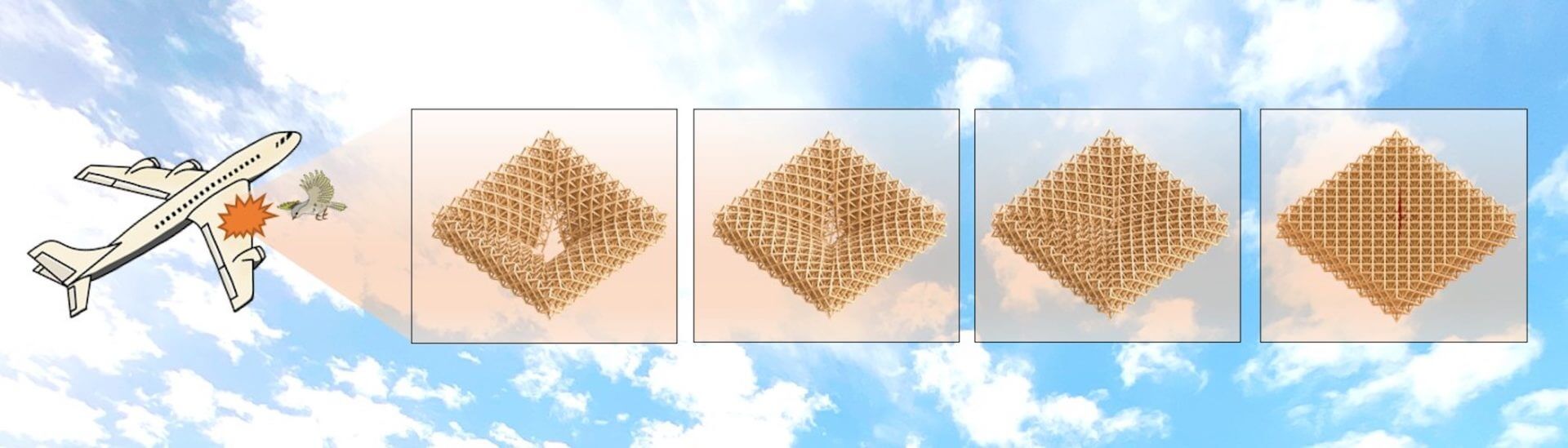

USC researchers have developed a new material that could fix such impact damage in the air, as soon as it occurs. The team, led by Qiming Wang, Stephen Schrank Early Career Chair and assistant professor in the Sonny Astani Department of Civil and Environmental Engineering, created 3-D lattice structures—structures that feature repeating cells—that will autonomously recover from impact damage, first restoring the structure’s original shape and then healing the fatal fractures or breaks in the material.

“Traditionally, lattice structures, while lightweight, have low damage tolerance, meaning if there is impact, it will easily spread, eventually compromising the structure. The material we created has high damage tolerance,” Wang said.

The new material is characterized by high strength and stiffness. Unlike traditional self-healing materials, Wang said, in the event of a fracture, no manual intervention is required. “You do not have to push the fractured pieces back together to allow for healing of the material,” Wang said. “The shape memorization characteristic of our new material means the fractured pieces will align themselves back to the original shape autonomously, prior to beginning healing of the individual bonds.”

The researcher team includes: USC Viterbi Ph.D. students Kunhao Yu, Haixu Du, An Xin, Kyung Hoon Lee, and Zhangzhengrong Feng; Professor in the Sonny Astani Department of Civil and Environmental Engineering Sami F. Masri; Professor in the Daniel J Epstein Department of Industrial and Systems Engineering Yong Chen; and University of Missouri Department of Mechanical and Aerospace Engineering Professor Guoliang Huang. Their work was published in Nature journal NPG Asia Materials.

What if a bird hit a plane made of self-healing material? The researchers demonstrate how the damage would first correct for shape damage and later, heal broken bonds. IMAGE/Qiming Wang.

Self-healing, Shape Memorizable and Photocurable

3-D lattice structures are not easy to fabricate. Said Wang: “The existing method—layer by layer laminate assembly—is time-consuming.” However, Wang said, to be able to use 3-D printing, you are restricted to specific materials. These materials lack the properties necessary for autonomous self-healing.

To create a new material that had all the desired characteristics, the researchers built on a prior innovation: a more rubber-like self-healing material featuring dynamic bonds (disulfide bonds) that trigger self-healing. When these bonds break apart, the application of heat pushes them back together to reform the original bonds. While self-healable, the rubber-like material was too soft to support much weight.

In order to incorporate the properties necessary to meet their goals, the researchers added crystalline domains—polymers with high rigidity and responsiveness to heat. “The material is strong like Teflon. In our studies, we found the material could support 1,000 times its own weight,” Wang said.

When the researchers incorporated the crystalline domains, they also added another key property: shape memory, meaning the polymers memorize the structure’s original shape.

To meet all their goals, the researchers also added the acrylate chemical group (often used in adhesives), which made the material photocurable, or reactive when the material is exposed to light. This property was essential to the use of a 3-D printing technique called stereolithography, by which light causes the liquid material to solidify layer by layer to form solid lattice structures.

The Two-Step Process of Healing

When impact damage occurs, a material usually exhibits two forms of deformation: a dent or shape change and structural fractures (broken bonds). Traditionally, with existing self-healable materials, Wang said fractures could be healed, but not until manual realignment of the fractured pieces occurred—basically pushing the object back together to its original shape. With the new material, shape recovery and fracture repair both occur autonomously, with the application of heat.

The process begins with the impact. Once a structure is damaged, remote heat—applied at 80 degrees Celsius (about 176 degrees Fahrenheit) in the study—is applied to begin the shape restoration process. In this case, the researchers created a lateral wing and smashed a weight into it. Once damaged, the heat was applied. The original shape of the wing was restored within two minutes. Under continuous heat, the fractured pieces begin to reform bonds and heal. After six hours, the material returned to its original strength and structure.

In this study, the researchers completed ten cycles of damage and healing with the same structure. Even after the tenth cycle, the structure maintained the same level of mechanical integrity as originally.

Planes, Trains and Automobiles

These new lattice structures could be used to reinforce any number of vehicles, from airplane to automobile. “When there is an accident, repairing dents and cracks on a car body is always very troublesome,” Wang said. “But if the car body were made of our new lattice structures, this repair could occur autonomously, returning the body to its original shape and function, without additional cost or excessive repair times.”

Practically, Wang sees this material working along with sensors. If the sensor picks up on impact damage, a heater will be triggered, beginning the healing process. Other applications include defense vehicles, such as tanks, or bullet proof vests/armor. Wang said this material could offer longer usage periods and better damage tolerance for key parts.

Another application is a direct result of the shape memory and healing characteristics themselves. Wang said that if you cut or alter a structure to transform it into another—for example from a triangle to a kagome (star-based) shape, you can tune the material to exhibit different qualities, for instance, damping versus transmitting certain vibration frequencies. Once such a use is complete, applying heat will return the structure to its original form.

This research was funded by the Air Force Office of Scientific Research Young Investigator Program (FA9550-18-1-0192,program manager: Dr. Ming-Jen Pan) and the National Science Foundation (CMMI-1762567).

Published on March 27th, 2020

Last updated on April 8th, 2021