The Information Sciences Institute will administer a pilot effort to demonstrate how small manufacturers can effectively use sophisticated high performance computing (HPC) industrial design.

ISI Project leader Brian Schott will be working with computer scientist Lorin Hochstein on the effort, which will be run out of ISI’s Arlington Virginia campus as part of a $3.67 million DARPA contract.According to Robert Graybill, ISI division director for its National Innovation Initiative, recent studies by the Council on Competitiveness suggest that high-performance computing (HPC) can help engineering companies address problems in their existing design processes.

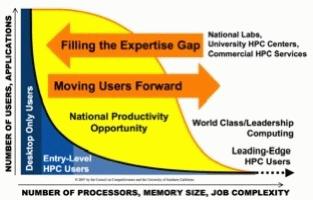

But the same studies find that many companies are deterred by the high cost of obtaining HPC resources and a lack of expertise in use of HPC systems, continued Graybill, who played a key role in bringing the HPC-ISP-PILOTS project into existence. The object is to demonstrate how barriers to HPC utilization can be overcome in companies in the Department of Defense supply chain to increase productivity and competitiveness by reducing the amount of expensive physical testing required.

In the four pilot efforts researchers will provide support for introducing HPC to companies.

On the first of these contracts, an ISI team will be working directly with Woodward Control Solutions, a supplier of fuel injection systems for DoD supply chain vendors such as Pratt & Whitney. This case study will show how the use of HPC can more accurately model the behavior of fuel nozzles designed for Pratt & Whitney engines.

Hochstein says that HPC at Woodward will allow complete analysis “over the entire design envelope” to eliminate costly design turn-backs and design escapes.

Turn-backs lead to additional design cycles and expensive physical prototype fabrication and testing. Design escapes result in costly product recalls and field service interruptions.

Three other contracts are part of the initial work.

IAP Research: Led by the Ohio Supercomputing Center, this case study involves IAP Research, a recognized leader in the field of electromagnetics. This case study will show how the use of HPC will enable a more complete analysis of the electromagnetic interference generated by power electronics in naval vessels.

AlphaSTAR / Composites DOC: Also led by the Ohio Supercomputing Center, this case study involves Alpha Star, a provider of engineering analysis services and specialized software in advanced composites and metal materials and structures simulation, and Composites DOC, a consulting company focused on the design and optimization of composite structures. This case study will show how HPC will enable redesign of several components in military vehicles, allowing weight savings by using composite materials.

ACE Clearwater: Led by California State University, Los Angeles, this case study involves Ace Clearwater, a company that builds complex formed and welded assemblies for the areospace and power generation issue. This pilot will demonstrate how HPC can reduce a small company’s reliance on physical prototyping and shorten the manufacturing cycle of DoD components.

The project will also look for and learn from other down-supply chain HPC success stories that have occurred in industry.

HPC-ISP-PILOTS is part of the National Innovation Collaboration Ecosystem (NICE) jointly led by the Council on Competitiveness and USC Information Sciences Institute.

(Approved for Public Release, Distribution Unlimited).

Published on January 13th, 2009

Last updated on August 5th, 2021