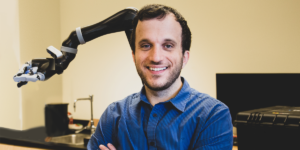

The first place team from USC’s Center for Advanced Manufacturing. From left to right: Matthew Buckley, Professor S.K. Gupta, and Brual Shah. Photo/S.K. Gupta

The National Institute of Standards and Technology (NIST), in collaboration with the Institute of Electrical and Electronics Engineers (IEEE) and the Open Source Robotics Foundation (OSRF), held their first annual Agile Robotics for Industrial Automation Competition (ARIAC), concluding earlier this month. First place was awarded to a team from USC’s Center for Advanced Manufacturing (CAM), including CAM Founding Director Satyandra K. (S.K.) Gupta, post-doctoral researcher Brual Shah, and undergraduate student Matthew Buckley (Computer Science ’18).

The world of manufacturing is no stranger to robotics. These programmable machines are perfect for the repetitive tasks often necessary in the production process. However, they are currently limited to pre-programmed moves, meaning they are unable to be quickly modified or reconfigured when an error occurs – traits that fall in the category of “robotic agility”.

“Robot agility refers to the ability of the robot to change its behavior in response to product change, production volume change and manufacturing facility changes. It is needed to reduce product realization time,” said Gupta, Smith International Professor in the Department of Aerospace and Mechanical Engineering (AME).

“If we can have researchers like S.K.’s group start to address challenges that industry is facing when incorporating robotics in their industrial systems, then we can find solutions for them to be able to solve their challenges and make them more productive and be able to do better in the global economy” – Schlenoff

As a part of the Department of Commerce, NIST works to promote industry and make the U.S. more competitive in the global market. Teaming up with IEEE and OSRF, they developed ARIAC as a way to start addressing these current obstacles in industrial robotics.

“We talked with various people from industry and we tried to understand the challenges that they were facing in using robots,” said Craig Schlenoff, associate program manager of robotics program at NIST and competition chair for ARIAC. “We then included those challenges in the competition to see how well teams could come up with interesting approaches in order to address those challenges.”

The entire competition was performed virtually, using a computer simulation of a robotic arm on a manufacturing shop floor, allowing teams to participate from home. They were tasked with writing a software program that gave the robot autonomy while completing pick-and-place kit assembly tasks. The robot needed to be able to overcome agility challenges, such as the suction gripper failing, the notification of faulty parts, and the reception of high-priority orders.

Simply put, “The main objective was to develop next generation robots that are intelligent and flexible,” said Gupta. Though the actual competition, consisting of three rounds of qualifiers before the final competition with 15 different challenge scenarios, was not so simple.

“We had to arrange parts on trays as quickly as possible, using as few sensors as possible,” said Buckley, who was responsible for writing the team’s software code. “The major challenges were getting everything working in a simulated environment, which can be unreliable and error-prone, as well as creating a solution that had a clear advantage over other teams.”

Submitted software was scored based on performance, efficiency and cost. The USC team, Realization of Robotics Systems, used the latter of which to optimize their system. By using less cameras, they were able to greatly reduce cost.

“The rules were such that a one camera solution was advantageous and enabled us to score more points. However, this solution was difficult to implement and increased the overall cycle or completion time,” said Shah, whose role in developing the logic and planning for their software is reflected in his research at CAM.

The 56 teams that registered for the competition consisted of researchers from educational institutions as well as representatives within industry, spanning three continents and bringing a world-wide perspective to the challenges at hand.

“That’s why we had this competition,” Schlenoff said. “If we can have researchers like S.K.’s group start to address challenges that industry is facing when incorporating robotics in their industrial systems, then we can find solutions for them to be able to solve their challenges and make them more productive and be able to do better in the global economy.”

Published on July 14th, 2017

Last updated on July 14th, 2017