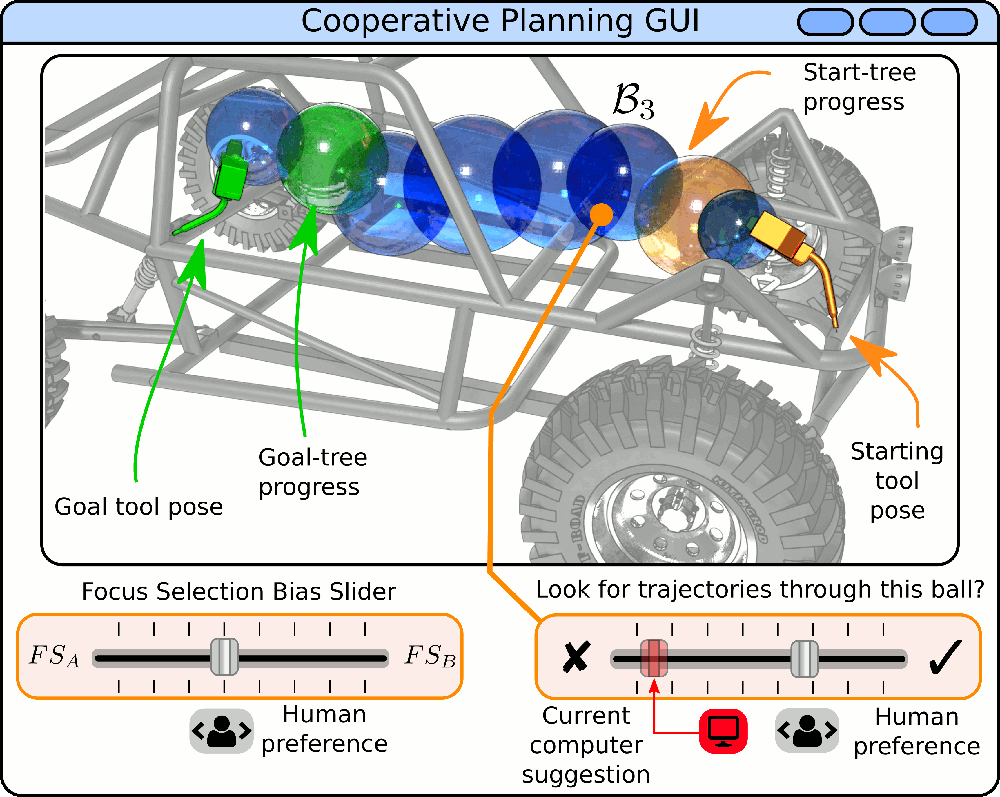

Using the researchers’ path planning algorithm, complex paths that typically take 15 to 30 minutes to specify manually can be generated in just a few seconds, bringing the tool from source to destination to complete manufacturing tasks without human help. IMAGE/Pradeep Rajendran.

Imagine a car assembly plant: thousands of repetitive tasks need to be performed on a daily basis, such as inserting a steering wheel into a car. Once the robot learns the best trajectory to getting from point A (where the wheels are stacked) to point B (where the wheel needs to be inserted), it can execute on this millions of times, without mistakes or collisions.

However, if this task is changed even slightly — for example increasing the wheel size — the robot will be unable to complete the task.

To help automate robots to provide high-quality solutions even in complex manufacturing scenarios, researchers from the USC Viterbi School of Engineering’s Center for Advanced Manufacturing (CAM) identified a new approach to automating robots’ paths through their workspaces. In research presented at the International Conference on Intelligent Robots and Systems on November 4, 2019 in Macau, China, the research team, including Professor SK Gupta, Smith International Professor in Mechanical Engineering and CAM director, and Ph.D. candidate Pradeep Rajendran, proposed a novel path planning algorithm and interface that guides robots to take the shortest, quickest route from a source point to a destination point in a workspace with minimal human input.

“We propose an approach for eliciting human feedback during the automated path planning for manipulators operating in very complex workspaces—for example, satellite assembly operations,” Rajendran said. “Typically, robot operators use an automatic path planner to plan a trajectory for the robot to complete the task within the workspace. If path planning fails—meaning the proposed trajectory doesn’t produce desired results—robot operators have to manually input waypoints—specific points along the path to guide the robot from its source to its destination.”

This situation arises more often in complex or confined workspaces, like the satellite assembly operation, where more difficult workspace geometries, physical obstacles and more frequent changes or customization require robots to execute complex paths. As a result, robot operators waste valuable time manually inputting information for each scenario, defeating the purpose of using automation in the first place.

The algorithm works by providing a user-friendly interface for the robot to gather human operator input early in path planning—the process of mapping the route the robot should take through the workplace to accomplish its task. The human operator is alerted, through visual cues in the program, to the more complex areas the robot will need to navigate and can provide information accordingly, to produce high-level directives. As a result, when the robot encounters slight alterations in its task—like the aforementioned wheel size increase—it will be able to draw on these directives and adjust its path accordingly.

The method devised by researchers in USC Viterbi’s Department of Aerospace and Mechanical Engineering — which also includes post-doctoral research associate Ariyan Kabir, Ph.D. student Shantanu Thakar and CAM research scientist Brual Shah — prioritizes automation, ensuring that the path planning program only elicits help when it is needed. It typically takes 15 to 30 minutes to specify a path manually; with the path planning algorithm, the path can be generated within a few seconds.

This image shows a shows cooperative-planning graphic user interface, as applied in a roll-cage assembly welding setting. The path planner is initially tasked with moving the welding tool from “starting tool pose” to “goal tool pose.” If the path planner encounters difficulty in producing a solution, it notifies the human operators, who will then create a string of balls that constitute a hint as to how the robot should move from “starting tool pose” to the “goal tool pose.” Human operators can move the balls, resize the balls and essentially deform the string of balls until the path planner is able to exploit the given hints. IMAGE/Pradeep Rajendran.

“In small volume manufacturing, robots perform many non-repetitive tasks that change frequently. Programming robots for each of these iterations of tasks is not only time-consuming, it’s tedious and inefficient,” Rajendran said. “With this new algorithm, we demonstrate that many non-repetitive processes encountered in small volume manufacturing applications can be automated easily, with minimal input from human operators.”

This work was supported by National Science Foundation grants #1634433 and #1634431.

Published on November 12th, 2019

Last updated on November 12th, 2019