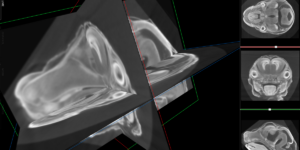

SprintRay is a leading supplier of 3-D printers that allow dentists to rapidly create custom products like night guards and dentures. Image/SprintRay

When two USC industrial and systems engineering graduates launched a Kickstarter campaign in 2016, little could they have known that in five short years the 3-D printing company they founded would become a leader in the dental industry.

Every human mouth is completely unique. When dentists need custom fit medical devices and products for their patients, such as dentures, nightguards, crowns, models and aligners, they often must outsource to external laboratories, which then craft the custom devices to each patient’s measurements. This results in costly lab fees and weeks of wait-time for the patient. But what if dentists could create these products in-house, quickly and affordably?

This was the opportunity that SprintRay co-founders Amir Mansouri (Ph.D. Manufacturing Engineering ’16) and Jasper Jing Zhang (Ph.D. ISE ’09) saw when they pivoted their company from a manufacturer of affordable desktop 3-D printers to a dedicated dental device innovator.

SprintRay has grown to become the leading supplier of dental 3-D printers within dental offices. The company also maintains close ties to the Daniel J. Epstein Department of Industrial and Systems Engineering. Along with Mansouri and Zhang, company president Erich Kreidler and director of operations Kazuo Takeda also lecture within the department. The team also works with professor of industrial and systems engineering Yong Chen on IP through the USC Stevens Center for Innovation.

Mansouri said 3-D printing was a natural fit within the dental industry, so he and his team considered the possibility of creating targeted 3-D printing technology for that sector, to produce parts on demand for patients.

“It was a vision that looked impossible four years ago, but that’s the reality now,” Mansouri said. “Now thousands of doctors have multiple of our units in their dental practices. They’re printing parts for patients—prosthetic teeth, night guards, dentures—while the patient is sitting in the chair.”

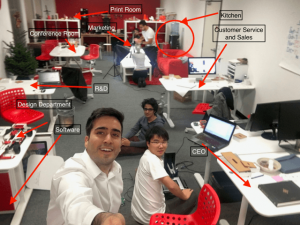

Amir Mansouri (foreground) and team at the first SprintRay office when the company was newly launched. Image/SprintRay

The technology is also allowing dentists to schedule fewer visits for their patients. Kreidler said that if patients needed dental surgery, they often required a surgical guide to be made from an imprint of their mouth, a process that would take weeks from a lab and would cost hundreds of dollars.

“Now the doctor can 3-D print while the patient is sitting there, so the patient doesn’t need to come back three weeks later, after enduring that pain,” Kreidler said. “Also, from an operational perspective, this 3-D printed version is only $4 worth of materials.”

Mansouri completed his Ph.D. at USC Viterbi School of Engineering, working with Louise L. Dunn Professor in Engineering, Berok Khoshnevis, on his NASA-funded research into 3-D printing in space. It was high-level innovation that inspired Mansouri, and demonstrated how USC Viterbi research could have a profound impact on humanity.

But Mansouri said he always had an entrepreneurial streak.

“Ever since I was 13 or 14 years old, I was buying things and then selling them – I liked the hustle.”

In 2016, while Mansouri was still a student, he and his team launched a Kickstarter for an affordable desktop 3-D printer. The campaign was a runaway success. It was a Kickstarter staff pick and raised over $400,000, allowing the team to launch the startup.

Demand from industry was also heating up, with companies such as Lockheed Martin and GE buying the early devices for avionics, and Disney and Marvel purchasing devices for use in developing custom materials for their Spiderman and The Lion King franchises.

But soon the team realized that by focusing on one sector and tailoring their expertise to it, they could have a stronger differentiator in the market compared with other 3-D printer companies. The dental industry was the ideal fit.

The SprintRay machines utilize a 3-D printing process that builds layers with a liquid polymer and UV light. After the part has been digitally designed, a dental appliance can be 3-D Printed in less than an hour. Existing solutions rely on labs, which can take up to 3 weeks to deliver the dental appliances.

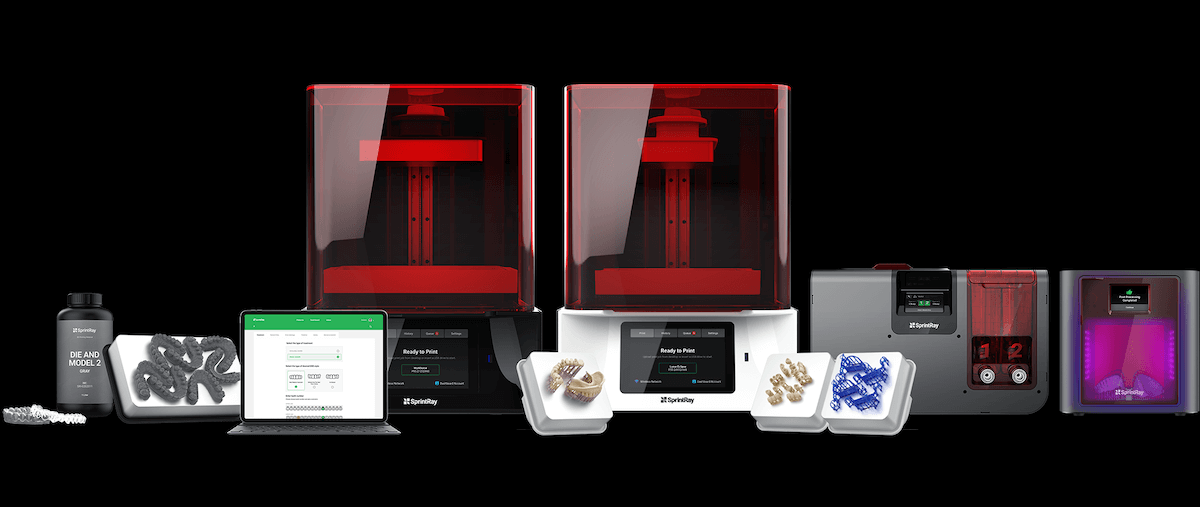

The range of SprintRay 3-D printers and products. Image/SprintRay

“Different applications in dentistry require different performance, so we developed a portfolio of products for those different applications,” Mansouri said. “For example, one of our printer models is a dental crown printer, and it’s perfect for implant cases and dentures. Another one is best for orthodontists and another is good for night guards.”

The products also include a wash unit and post-processing equipment that helps users refine the finished devices. The system allows dentists to create complex custom items such as denture models in 30 minutes to an hour. The response from dental providers has been positive.

“We’ve had a lot of great stories, such as how a grandma showed up at a dental office last minute because she had a wedding coming up the next day and had a broken denture. The doctors had the ability to replicate that denture on the spot for her,” Mansouri said.

“We have built an amazing ecosystem to enable digital transformation in the dental industry, Kreidler said. “We have been fortunate to partner with industry giants to integrate technology that delivers a solid dental workflow supported by 3-D Printing.”

The current SprintRay team outside their Los Angeles facility. Image/SprintRay

Takeda said that SprintRay was founded with industrial and systems engineering approach, which gave the company a strong business advantage.

“Our two founders, president and director are industrial engineers. The way we look at challenges as opportunities and understand the difference of a symptom rather than a problem allows us to make course corrections faster and to avoid issues before they happen,” Takeda said.

Next up, the team is looking at ways to collaborate with USC Viterbi students, as well as further global expansion of their company. They recently opened subsidiaries in Germany and Canada, as well as operations in China, and are working with distributors worldwide. The SprintRay team is currently employing Trojans from around the world and are actively recruiting ISE and other engineering talent.

“So a little bit of passion, a lot of vision, perseverance, resilience and meeting the right people along the way were all the factors were involved in getting off the ground,” Mansouri said.

Published on July 30th, 2021

Last updated on July 30th, 2021