USC Viterbi students Vineeth Rajesh and Justin Lockwood make “SC” themed pancakes with the help of a Baxter robot. PHOTO/AVNI SHAH.

Gone are the days when you need to measure out your pancake batter or spend far too long perfecting your pour-over method. Now, breakfast is served with a side of robot.

USC Viterbi School of Engineering students explored robotics at the Center for Advanced Manufacturing (CAM) this semester in order to bring to life the most important meal of the day—breakfast. For Justin Lockwood and Vineeth Rajesh, a junior and freshman in the Department of Aerospace and Mechanical Engineering respectively, making pancakes using a Baxter robot offered a creative way to explore the topic of “robot manipulation of nonrigid objects,” as part of their CURVE research fellowship. SK Gupta, professor of aerospace and mechanical engineering and director of CAM, was their adviser.

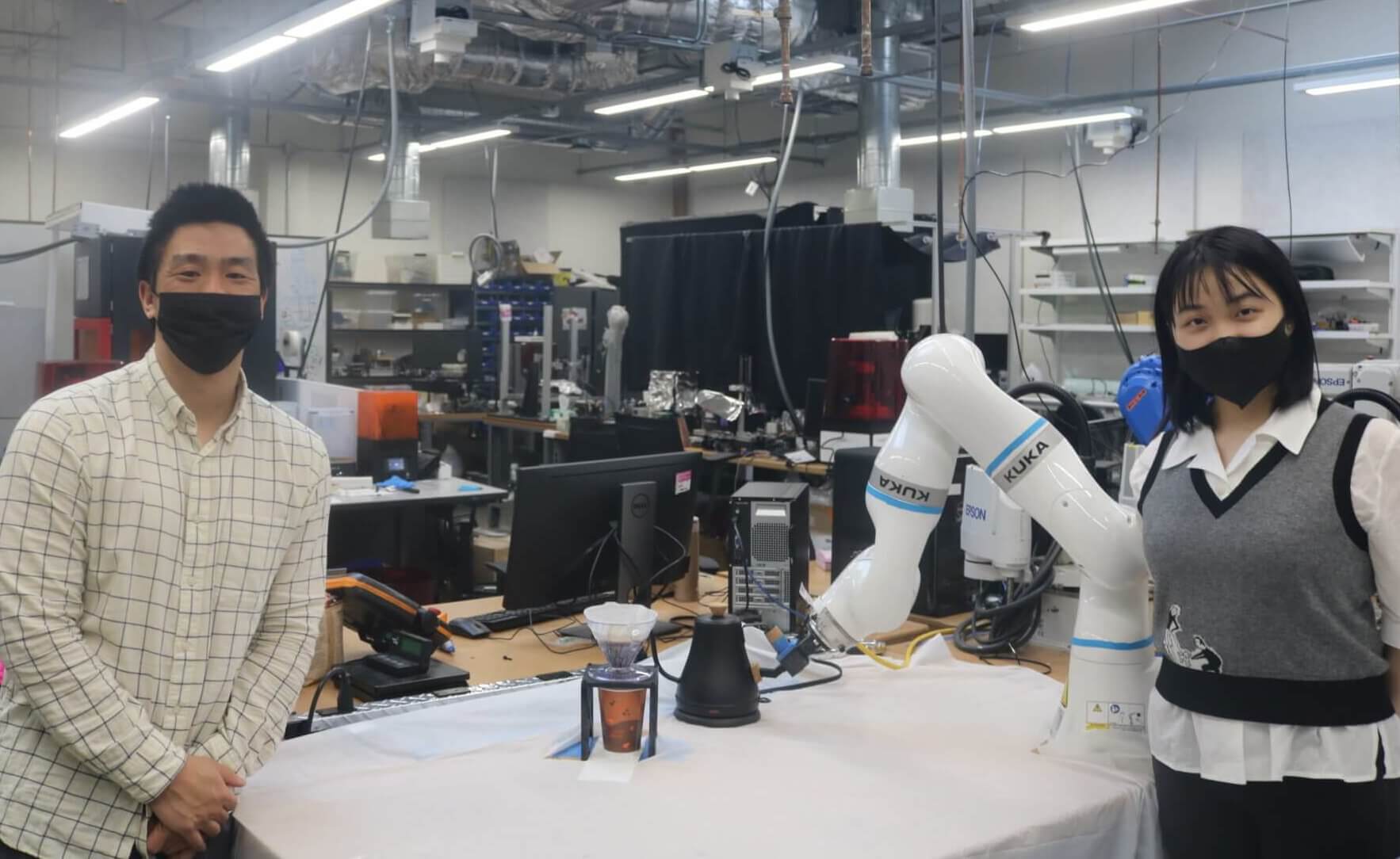

For master’s students Anthony Tran and Yang Yang, making coffee using a robot seemed like the perfect challenge for their first experience working with a robot as part of AME 547 “Foundations for Manufacturing Automation,” taught by Gupta, the Smith International Professor in mechanical engineering. In each case, the students experienced a steep learning curve and developed a solid foundation in a skillset that is becoming more than nice-to-have, but essential in many industries across the engineering space.

A Perfect Cup of Coffee

Anthony Tran is more than a coffee lover, he’s a bona fide enthusiast. At home, he has an elaborate espresso brewing setup that rivals your local coffeeshop, all in an attempt to make daily that oh-so-perfect cup of brew. When he and Yang Yang partnered for a project in robotics for Gupta’s manufacturing automation fundamentals course, there was one process he was jazzed about perfecting: pour-over coffee.

The team brainstormed ideas, considering cost, feasibility and intrigue factor. With a timeline of three weeks, latte art proved too difficult to tackle, but coffee continued to prove inviting.

Said Tran: “I have a palate for coffee and wanted to try to make the best cup. It’s a big part of everyone’s lives—and it’s a multibillion-dollar industry.”

In fact, 62% of Americans drink at least one cup of coffee a day, and 43% of coffee drinkers under 30 opt to purchase their daily brew and rely on the convenience and expertise offered by baristas. Tran and Yang were inspired by the art of coffee making, noting it is a very meticulous process—one that could be difficult to recreate in a robot’s hands.

They began the programming process by researching methodology. How does one create the best cup of coffee? Tran and Yang took note of a specific method, touted by a Japanese barista Tetsu Kasuya, who won the 2016 World Barista Competition. Kasuya says that anyone can make delicious coffee. Tran and Yang extrapolated this, learning from his very precise water measurements and pour-over strategy to redefine the “anyone” in the equation to include a robot.

Master’s students Anthony Tran and Yang Yang programmed a robot to make the perfect cup of pour-over coffee. PHOTO/AVNI SHAH.

First steps included identifying the hardware. The team used computer-aided design (CAD) to 3D print an object that mimicked the human hand and could hold the V60 gooseneck kettle they ordered online. Using a 3D scanner, they were able to grab specifications recreating the complex curvature of the kettle and print the hand-like object.

From there, the team looked at the software. While Yang had a basic understanding of the robot operating system (ROS) from her freshman year course in computer science, this area was completely new to Tran. For both of them, RROS presented the biggest challenge in completing their project.

“Planning the trajectories was really important, because planning where to make the robot go—and the circular motion required for the pour-over—was essential in making the coffee,” Tran said.

At first, the team could only make the robotic arm pour in a half circle. “Knowing the robot library was difficult,” Yang said.

Beyond programming trajectories, there were a number of technical aspects to the software design, including creating a dialogue in the user interface regarding desired flavor and strength of the brew. Based on these user inputs, the robot determines how much water should be poured and when.

Yang also said they had to be specific about the placement of the robotic arm. “The angle is important, because how much the robot tilts the kettle will determine how much water is dispensed—and whether it is the right amount for the method. How the coffee tastes will depend on how fast the water is poured and how much water is poured,” she said.

The team also struggled with time constraints, one of the reasons they did not fully automate the entire process. “We still need a human to grind the beans and switch on the kettle to boil the water, but in the future, this could all be automated.”

Beyond creating an excellent cup of coffee, the team said they learned fundamentals that will make them competitive for future opportunities. “The world is going towards automation of more processes,” Tran said. “Being able to work on this now opens up more doors.”

Said Yang: “I had no experience in robotics before this, and it ignited my passion for coding again. I have a lot of interest in advanced manufacturing, which is becoming more and more reliant on automation.”

Batter in All Shapes and Colors

USC Viterbi’s Center for Undergraduate Research in Viterbi Engineering was launched in 2021 to provide undergraduates mentorship and hands-on experience in research labs. As part of CURVE, mechanical engineering students Justin Lockwood and Vineeth Rajesh sough to gain experience in robotics—specifically, food-related experience, which they felt posed an added challenge.

“As beginners, neither of us knew ROS,” Lockwood said. Rajesh had to learn MATLAB and Lockwood had to learn Python—programming languages that allowed them to manipulate the robot’s software.

The main challenge in getting the Baxter robot to make pancakes was figuring out how it could hold and dispense the batter onto a griddle or pan, the students said.“We went through several 3D prototypes,” Rajesh said. “Some were too big and too heavy for the robot’s arm to hold and it would start shaking.” The team also wanted to make sure that the robot could differentiate between two separate colors (dispensers) of batter, so the robot could create designs. This required using MATLAB to separate the colors and create trajectories that were equally spaced and didn’t overlap with each other. For this, they had to measure the width of the batter coming out of the nozzles and submit those in MATLAB.

An additional challenge was making sure the dispenser was food-safe. Since the 3D printed material itself was not food-safe, they used a piping bag as a reservoir to hold the batter.“It was a pretty steep learning curve the first couple of weeks,” Lockwood said.

For Lockwood and Rajesh, it wasn’t just robotics that they were diving headfirst into, but the idea of hands-on research and problem-solving. Said Lockwood: “It was my first-time ever doing research like this, so I was pretty unfamiliar with the process. We broke down each problem into smaller problems, and then worked to solve those one by one.”

Another key lesson, Rajesh said, was not being afraid to ask for help. Each student was assigned a Ph.D. mentor as part of CURVE. The team also relied on graduate students and faculty at CAM for guidance, as well as their adviser, Gupta.

A young visitor enjoys a bunny-shaped pancake made by the Baxter robot. PHOTO/AVNI SHAH.

After two months, the team programmed Baxter to successfully drop batter in shapes including a bunny, smiley face and classic “SC” letters using two separate batter dispensers and colors (cardinal and gold, naturally). If they were to take the project further, they said they’d try to get the robot to use its other hand to flip the pancake or add chocolate chips. They also were inspired at the thought of using AI for creativity—“What if we could have the robot come up with its own design?” Rajesh said.

Rajesh said one of the main reasons he chose CURVE was to gain experience in AI and robotics. An early experience as part of a Carnegie Mellon competition he entered during high school in Qatar sparked his interest in robotics, while working on how to increase efficiency of wind turbines with a scientist in India confirmed his love of mechanical engineering.

Lockwood got his engineering inspiration working on cars growing up in Bloomington, Minnesota. He said, “It’s very clear that the way the world is going, robotics is going to be used more and more in industries like manufacturing.”

Published on January 12th, 2022

Last updated on January 12th, 2022