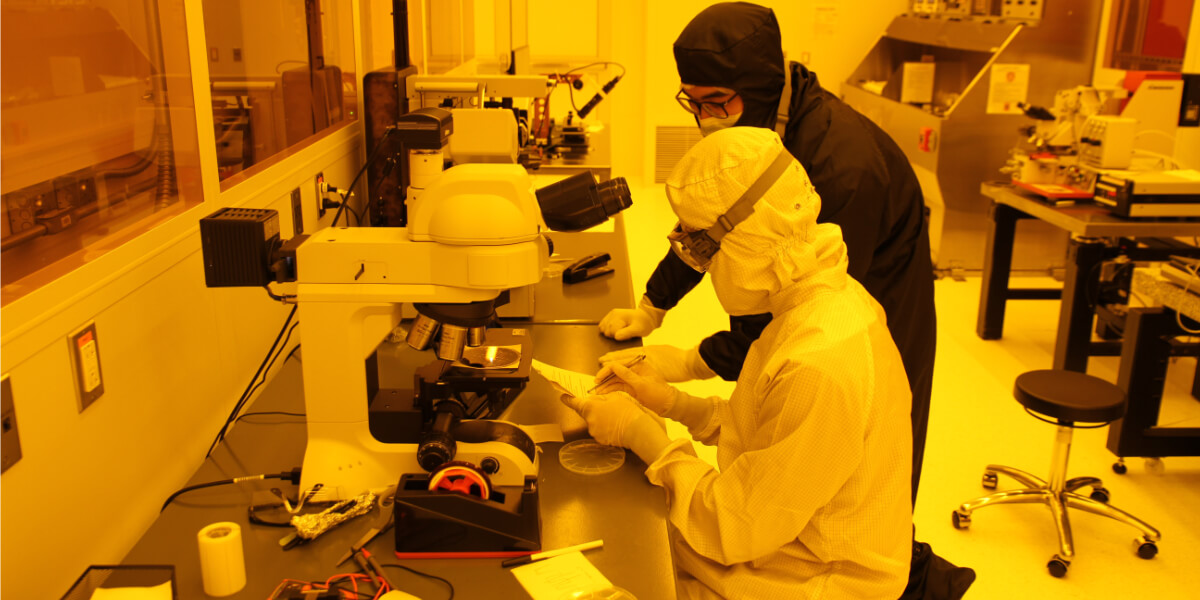

Photo Credit: Jonathan Van Dyke/USC ISI

Like many of her peers, USC sophomore Cecilia Betancourt receives a lot of emails each day, many littered with opportunities on and off campus, but few catch her attention. However, this spring, she noticed something unique that she didn’t want to pass up: the Undergraduate Microelectronics (ME) Commons Scholars Program presented by the California Defense Ready Electronics and Microdevices Superhub (CA DREAMS).

“I’m pretty interested in semiconductors,” said Betancourt, an electrical and computer engineering major. “But I’ll be honest, I didn’t know a ton about them yet, and I’ve only just begun learning more about them as I get into my major and get into more niche topics instead of just the basics. Seeing an opportunity for hands-on experience — I was really excited, so I decided to apply.”

Betancourt, along with 11 other undergraduate students, made up the pioneering first two cohorts of the ME Commons Scholars Program, which began this summer. The program was divided into two sections. Students first completed the two-week CA DREAMS Cleanroom Gateway where they received training and instruction at the USC’s John O’Brien Nanofabrication Laboratory. Then they embarked on a six-week internship at the same facility.

Led by USC Viterbi’s Information Sciences Institute (ISI), CA DREAMS is one of eight regional innovation hubs established under the Department of Defense Microelectronics Commons Program, which is funded by the CHIPS and Sciences Act of 2022 to develop onshore microelectronics hardware prototyping, lab-to-fab transition of semiconductor technologies and extended semiconductor workforce training.

Hands-on earlier on

For years, keeping students engaged in electrical engineering and pointed toward career paths in the semiconductor and microelectronics industry has been a challenge. A study by the National Academies has shown college enrollment in electrical engineering has remained relatively flat since 2009. One of the promises of the Microelectronics Commons Program is to innovate new ways to inspire the next generation of workers. Part of that challenge is that many students are drawn to computer engineering and computer science.

“When we think about electrical engineering, a very large percentage of our students get shuttled into computers, and very few get into the other aspects,” said Sandeep Gupta, professor at the USC Ming Hsieh Department of Electrical and Computer Engineering. “Our curriculum doesn’t expose students to a lot of the other topic areas early, and we miss our chance. We’re not exposing them to microdevices and fabrication.”

But building microdevices and semiconductors is where information meets physics, he added. There are numerous devices designed for, and then built in, a cleanroom. “There is a very broad range of devices. There is a lot of work that goes into these tiny devices that have changed the world and will continue to change the world.”

The ME Commons Scholars Program exposes students to research faculty laboratories earlier in their academic studies; advises students on what companies to apply for after they have completed the program; and counsels students on what courses they should take to continue forward in the field.

Out of the classroom and into the cleanroom

While it took a moment to acclimate to the cleanroom, students said it was exciting to work more directly on what they were learning about in the classroom. “I’ve only ever heard the buzzword of cleanroom. I’d seen the photos of the people dressed in the white suits. But otherwise, it was sort of a black box — you’d just pass a design in and get the physical thing back,” said Austin Tsai, USC sophomore in engineering and computer science. “I thought it would be interesting if I understood what is behind the curtain of manufacturing and actually do it myself. You can’t really learn that on YouTube or other online resources.”

Instructors said the first two cohorts of students quickly found their bearings during the initial two-week Cleanroom Gateway training, where they created art wafers and neural probes — a highlight for many students. Then they were put to the test in six-week internships where they assisted Ph.D. students and research groups on special projects. The scholars also helped create training videos for process recipes — the steps taken on cleanroom machines to create semiconductors and microdevices.

“We are training the students about what we and the industry need,” said Shivakumar Bhaskaran, associate director of the John O’Brien Nanofabrication Laboratory. “These were some of the top students at the engineering school. They were able to grasp things immediately. It was a great experience for us, so hopefully next year we will continue adding to this course and bring in even more students.”

“My experience has been absolutely great,” said Cedar Rose Leach, USC sophomore in electrical and computer engineering. “It’s really cool to actually see what goes on behind the scenes of a device. I feel like in my classes we learn all of these concepts — what does what and why it does it — but we actually never really understood how you can create it and how you can make these semiconductors. And now I get that experience here, which is great.”

Leach said the eight weeks was a bit of a whirlwind, but she appreciated all the different tools and processes she learned. “Honestly the whole experience is kind of unreal,” she said. “One moment you’re above ground in fresh air, and then you get all suited up and go to the basement. You’re working with these crazy-level machines. You see all the years’ worth of research put into this to make a cleanroom possible and to make semiconductor nanofabrication possible. Just physically being in the suit. You’re all covered up. None of your body is exposed. It’s a very different way to work than being at a desk.”

Gupta said he hopes the program will expand to include students from across more disciplines such as physics, chemistry, chemical engineering, material science, mechanical and aerospace engineering. And he expects the next application period to be even more competitive..

“There are a lot of wonders here in the cleanroom,” he added. “Not only does the industry need these people, but our students need the wonder that exists in this industry. I have always felt that the semiconductor industry has a lot of wonder to it, we just don’t expose people soon enough.”

Published on October 23rd, 2024

Last updated on October 24th, 2024