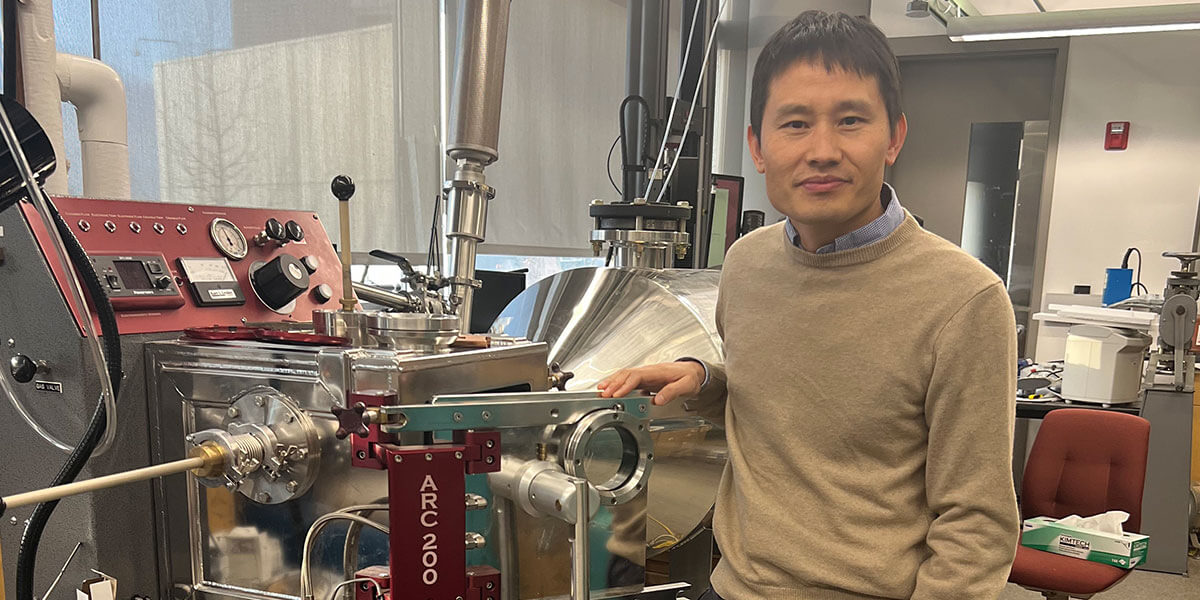

Associate Professor Wen Chen is developing new alloys with exceptional material properties

We live in a material world. That’s to say, the history of human civilization can be understood in terms of the properties of our materials and the experiments that have led to wholly new ways of living: from the sand transformed into concrete and glass, to the use of copper to conduct electricity, to lithium’s potential for renewable energy storage.nature

The alchemy of materiality has fascinated Wen Chen ever since he was a high school student in China. Now, as an associate professor of aerospace and mechanical engineering at USC, he draws upon that early obsession to investigate the possibilities for new metal alloys.

“Processing a material in different ways will result in dramatically different material properties,” said Chen. “You can make copper that is very soft, or you can make it stronger than steel.”

The advancement of 3D printing technologies in recent years has kept pace with Chen’s curiosity. Recognizing that traditional metal alloys were intended for conventional manufacturing (such as high-strength aluminum alloys used for aircraft parts), Chen specializes in the development of metal compositions tailored for additive manufacturing.

“Developing new alloys is very similar to cooking,” he reflected. “You change the ratio of ingredients and the method of cooking – tempering, fermenting, sautéing – and suddenly you find you have a material with a novel set of ‘flavors’ or superior properties.”

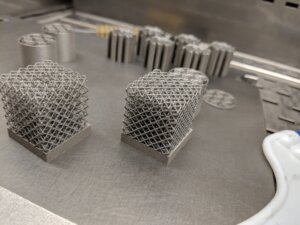

Chen’s experiments are all the more necessary because standard alloys have a tendency to crack or deform when 3D printed. Likewise, conventional cutting machinery is often labor-intensive and limiting when it comes to creating compact geometries for efficient design.

Lightweight yet strong metal lattice structures and aerospace components produced by metal additive manufacturing (3D printing) in Chen’s lab

“Rather than a ‘top-down’ approach of cutting the materials and generating waste, we’re interested in ‘ground-up’ additive manufacturing processes which grant us the freedom to build a structure block by block,” Chen explained. “As a result, you don’t encounter the problem of discarded offcuts – the process is more sustainable and leads to more opportunities for innovation.”

What does this look like in practice? In 2022, Chen and his research group published a highly-cited paper in Nature demonstrating the exceptional material properties resulting from new alloys and advanced manufacturing techniques.

High-strength nanostructured alloys produced by laser additive manufacturing often have limited ductility (the extent to which a material can be stretched or bent without snapping). In this case, an alloy was produced that demonstrated a yield strength of approximately 1.3 gigapascals and a uniform elongation of about 14 percent, far surpassing other state-of-the-art 3D printed metal alloys.

“Just imagine using an alloy with these properties for building cars and airplanes,” said Chen. “The higher the strength, the more you can reduce the weight of the vehicle. That has significant implications for energy efficiency in transportation systems.”

3D-printing also opens up a whole new set of design possibilities, playing with compact geometries to produce structures the human mind has never considered before. Chen shares the example of the airplane turbine blades currently being developed by companies such as Boeing, using additive manufacturing technologies to create highly compact internal structures.

“It’s crucial that the blades don’t overheat as they spin, so it’s necessary to integrate compact cooling channels to actively reduce the surface temperature during operation,” Chen explained. “The geometrical dexterity required for this type of high-performance design and materiality is almost impossible to achieve by conventional machining.”

For Chen, who made the move from UMass Amherst to USC earlier this year, USC’s proximity to the Southern California aerospace industry is an opportunity to boost knowledge transfer between academia and industry. His research into the fundamental properties of materials also complements the work taking place at the USC Viterbi Center for Advanced Manufacturing (CAM), recognized for innovation in robotics-controlled manufacturing.

“We’re planning to bring our unique expertise in materials science and manufacturing to further advance the projects at CAM, many of which are industry-sponsored,” said Chen. “That allows for a direct path between the study of material properties and impact on the technologies that define everyday life.”

The path, however, is not without its challenges. As the best chefs know, some of the most extraordinary new forms and flavors have been the result of happy accidents –the tarte-tatin placed upside-down, the corn kernels exploding into popcorn. Likewise, the development of new engineered alloys is still primarily a process of trial and error – experimental, but not yet highly efficient.

“We’re working on developing a computational approach that will allow us to experiment and screen new materials faster and with a higher output of a range of results,” said Chen. “Working with researchers across the different departments at USC Viterbi, we have the opportunity to collaborate with faculty member specializing in high-fidelity simulations and computational models to help us to iterate experiments digitally and predict results, enabling us to reach solutions far faster.”

As an engineer, Chen now finds himself taking an active role in the metamorphosis of human civilization that fascinated him as a high school student.

“From the Stone Age, to the Bronze Age, to the Iron Age, through to the new materials we’re creating today, the story of materials and the trajectories of human technology and culture are inseparable,” Chen reflected. “We make materials, and materials make us.”

Published on August 4th, 2025

Last updated on August 4th, 2025