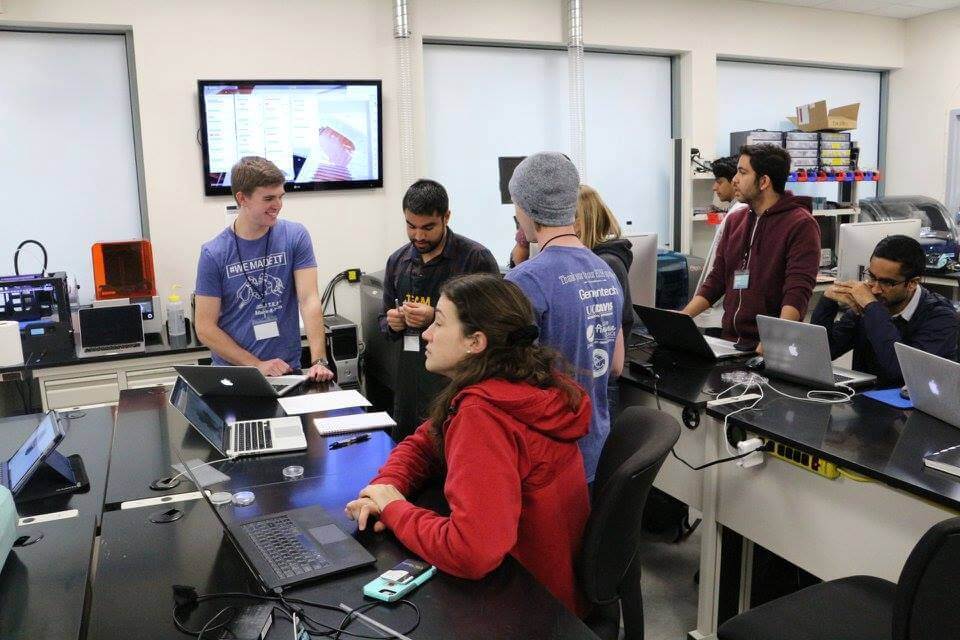

USC MedDesign Team working hard on the prototype that eventually won the competition Photo courtesy of USC MedDesign Team

The Translating Engineering Advances to Medicine (T.E.A.M.) Medical Make-a-thon at the University of California, Davis is an annual design competition that sees students team up to use computer-aided-design (CAD), 3D printing and laser-cutting machines to build a functional device to solve a medical or clinically-related problem in 48 hours or less. This year, the challenge was for students to build a device that speeds up the production process of gel plates used in the diagnosis of coccidioidomycosis – a soil fungus native to the San Joaquin Valley of California — hence, its other name, Valley Fever.

This year, four students — Hope Miller, biomedical engineering ’18; Margaret Field, mechanical engineering ’19; Michael Kyzar, computational neuroscience ’20; and Andrew Yock, biomedical engineering ’21 — from the USC MED-Design beat 14 other teams that included students from UC Davis, UC San Diego and San Jose State University, to claim the number one spot in the competition.

What is coccidioidomycosis?

Unlike most soil fungus pathogens, coccidioidomycosis infects healthy mammals, including humans, via air-bone arthroconidia, or spores. The acute state of the disease is endemic to California and progresses to a chronic infection in approximately three of every 100 affected individuals. It disproportionately affects underprivileged populations and immunocompromised patients including expectant mothers and people living with HIV/AIDS.

In overcoming the challenge, students had to ensure that their devices could produce diagnostic plates that were consistently error-free of common lab errors such as well shape imperfections, incomplete gel plug removal, and bubbles beneath gel that appear from excessive suction. The winning team got the chance to see their device implemented in the UC Davis Coccidioidomycosis Serology Lab.

“We ended up using plastic straws in our design, and had to find a way to laser cut them into the shape we wanted.”

Margaret Field

USC designs the winning solution

Their winning design was a handheld stamp device made up of hollow, cylindrical straw cutting features with barbs on the interior circumference to cut wells into gel plates and to catch the gel plugs formed after the wells are cut.

Andrew Yock, the freshman who came up with the idea that lead to the winning design, said that the device was modeled after a tennis ball collecting tube.

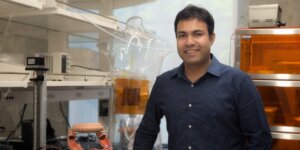

The winning design was inspired by a tennis ball collecting tube Photo courtesy of USC MedDesign Team

“We wanted cut out gel plugs to be stored in the device itself, pushing up the straws like a tennis ball collecting tube, so that they could end up in an upper reservoir on the devices which could be cleared by pouring the gel out,” Yock said. “A crucial decision we made was to avoid using negative pressure to remove the plugs out of the plates, deciding instead to just mess with the mechanical properties of the cutting surface so that it could pull out the plugs as well as cutting.”

To prove the feasibility of their idea to the judges in the second stage of the competition, the team had to build a prototype of their CAD design from limited resources.

“Our biggest challenge was with the materials provided,” said Margaret Field, a mechanical engineering junior on the team. “We ended up using plastic straws in our design, and had to find a way to laser cut them into the shape we wanted.”

Their approach impressed the judges.

“All the other teams used syringes or suction in their designs,” Field said. “Our first ideas did too, but that requires moving parts and air tight prototypes which are functionally hard to build.”

Speaking on her experience, Hope Miller, a senior on the team who aspires to work with biomedical devices after graduating, said: “The Make-a-thon was a great experience, and I would definitely recommend it to any BME student trying to get hands-on experience in the field. Working with the mentors was a major perk of the competition. I am still in contact with a few of them. It was also amazing to be surrounded by so many engineering students.”

Published on February 25th, 2018

Last updated on April 8th, 2021