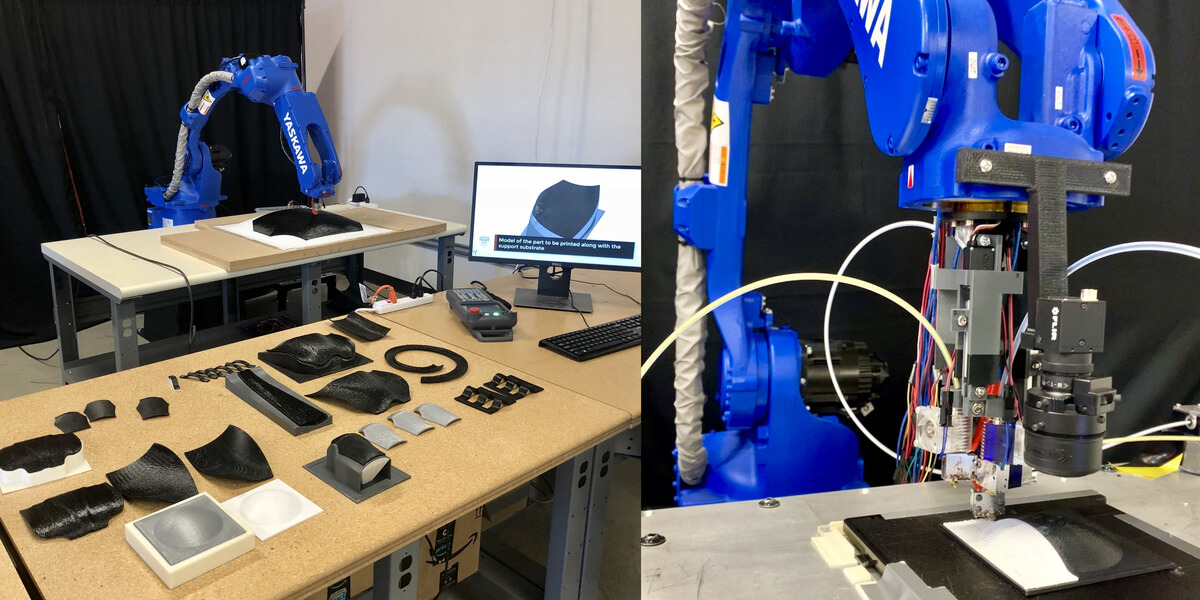

Robotic 3-D Printer. PHOTO/YEO JUNG YOON.

There are many things that make us nostalgic for the old days, even if they require more effort: handwritten letters, homemade bread, mixtapes. But in the world of manufacturing, traditional processes can represent increased cost, decreased flexibility and slowed production schedules.

While many industries have adapted 3-D printing to help facilitate speedier, more economic production, particularly for small batch products, it too has its limits.

“When it comes to complex geometries, for instance multiple curvatures or difficult overhangs, it can be very challenging for a traditional 3-D printer to print those parts well, no matter how much it tries,” said Yeo Jung Yoon, a USC Viterbi Ph.D. candidate in the USC Viterbi School of Engineering Department of Aerospace and Mechanical Engineering.

Yoon and a team of researchers at the USC Viterbi Center for Advanced Manufacturing (CAM), including Smith International Professor of Mechanical Engineering and Computer Science and CAM Director Satyandra Gupta, have spent the last year overcoming this problem—with robots. The team developed a robotic 3-D printing system, which would offer an alternative to traditional additive manufacturing process, improving the surface quality, reducing build time and enhancing mechanical properties of the final product. Essentially, an extruder, a tool which helps create objects with a fixed cross-sectional profile, is placed on the end of the robotic arm transforming it into a 3-D printer.

Coupled with an algorithm which plans out the path the robot will take to print a specific part, the team achieved faster printing with the robotic system than with a traditional 3-D printing option. The final product is also stronger mechanically, including supporting a higher load and demonstrating greater stiffness than the traditional 3-D printed piece.

“Because robots can orient the deposition head—a tool that lays down materials to build up parts—in any direction, deposit material on curved surfaces and change building directions while printing, they can tackle these complex shapes while improving on print quality,” Yoon said.

The research was published in the Journal of Computing and Information Science in Engineering and presented at the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference and at the International Conference on Robotics and Automation.

Building a 3-D Printing Robot

Additive manufacturing technologies, which create three-dimensional objects by adding materials layer by layer, have been widely used to reduce build costs and times. However, particularly with more complex designs, such as those with curvatures, traditional 3-D printing technologies can create many challenges, Yoon said.

Typically, a technique called material extrusion is used to construct 3-D parts; the material is fed through the extruder, where it is heated and then deposited on the build platform, layer by layer, Yoon said. In a traditional additive manufacturing set up, the 3-D printer is restricted to x and y axis movements — meaning up and down or left and right.

The researchers used six degree of freedom robotic arms, which allow for freedom of movement with regard to rotation and positioning (compared to three degrees of freedom, which only allows for positioning freedom). To convert these arms into printers, the researchers made custom extruders—a three-nozzle extrusion system, which deposit the materials—to attach to the ends of the arms.

With this setup, the researchers found they were able to orient material fibers at desired directions. Compared to a traditional 3-D printer, Yoon said the robotic printer produced parts with good surface finish, less layers and enhanced mechanical properties (e.g. high stiffness, high peak loads).

The researchers demonstrated numerous ways to enhance the robotic set up to improve upon different printing technologies. For example, using a three-nozzle extrusion system, where one extruder prints support materials and the other two print structural material with different resolutions, build time is significantly reduced and surface finish is significantly improved, Yoon said.

Path Planning Algorithms

To successfully print using the robotic 3-D printer, path planning—or mapping of the exact route the robot will take to build the prototype—is essential. In its absence, given the numerous angles and degrees of freedom to the robotic arm, collisions and disruptions are more likely.

Once successfully implemented, path planning can help save material, improve print speeds and reduce energy use. To ensure such optimization, the researchers generated sequences of positions and tool angles to optimize the robot’s path or approach to printing. For instance, while printing on a concave surface, there is the risk that an extruder tip will hit the substrate or already printed structure of it’s left in the usual default position, which is perpendicular to the surface. Thus, in path planning, different angles might be considered. Printing layers with varying fiber orientation has additional benefits: this process makes the output smoother and stronger, Yoon said.

Automating Industries

Aerospace and automotive companies benefit from additive manufacturing from both a cost and productivity standpoint. Said Yoon: “Companies used to need a lot of parts for a product, but now, with 3-D printers, a lot fewer parts are needed to build the same product.” Ultimately, these companies want to automate manufacturing and robots are a great solution to implement automation. In addition, when they are not used for 3-D printing they can be used for other tasks such as finishing, assembly and part handling, Yoon said.

Next up, Yoon and team members, including USC Viterbi mechanical engineering master’s students Oswin Almeida, Ashish Kulkarni and Aniruddha Shembekar and CAM Manager Alec Kanyuck, want to look at making this system smarter. They want to use AI to improve accuracy and efficiency. “When you print a complex part, there might be a gap between the filaments or oppositely, material accumulation in one spot. This is a common issue in both traditional and robotic 3-D printers,” Yoon said. “We want to print defect-free parts, first by installing a camera and taking a picture of printed samples, as well as recording when these defects are created. That way we can observe how different variables impact the process.” The data gathered from the camera will help train an algorithm to prevent conditions that create the defects, helping to print better parts.

This work is funded in part by the Viterbi Graduate School Merit Fellowship for Yeo Jung Yoon.

Published on March 13th, 2020

Last updated on March 29th, 2020