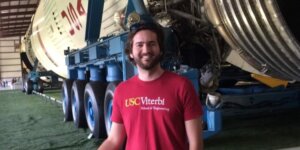

With the pandemic arrived the necessity for resilience and flexibility. In some cases, technology eased the way; in others, like for members of the USC Rocket Propulsion Laboratory, creativity and old school systems—like the US Post Office—saved the day. PHOTO/SHIVA BALACHANDER.

With the pandemic arrived the necessity for resilience and flexibility. In some cases, technology eased the way; in others, like for members of the USC Rocket Propulsion Laboratory, creativity and old school systems—like the US Post Office—saved the day. PHOTO/SHIVA BALACHANDER.

USC Rocket Propulsion Laboratory (USCRPL) has made groundbreaking student achievements. Much of its success has been derived not just from the technical prowess of its members, but from the creativity fostered through in-person collaboration and camaraderie. In fact, the lab space occupied on the USC University Park campus was not just where students built rockets; it’s where they completed homework, watched movies and connected with friends.

Of course, the global pandemic changed all of that.

Said Jeremy Struhl, USCRPL media lead, “At the time, we were working on a static fire vehicle that we were supposed to fire the week after spring break. It had to be put on hold.”

At first, Arpad Kovesdy, USCRPL lead design engineer, said they thought it would be temporary. “We kept thinking ‘When the university reopens, we’ll just resume our plans. But eventually, there came a time when we realized this might last a while and we had to take a different approach.”

The team focused on what they could do remotely, including design work on a new liquid bi-propellant engine and test stand. The team uses GrabCAD for Computer Aided Design; MATLAB for sharing files, GitHub for working on avionics and simulations files; Confluence as an internal wiki (database) to share information; and Zoom, to share designs, code and knowledge online, as well as to enable remote collaboration, said Kovesdy, an aerospace engineering major at USC Viterbi.

USC Rocket Propulsion Laboratory members got creative with staging their designs. Here, a rocket is propped up on a member’s front porch to allow for alignment of its fins. PHOTO/SAM NOY.

Luckily for USCRPL members, a lot of the required technology was available online and already loaded onto their computers. However, some things required a physical touch.

Said Kovesdy: “We’d ship electronics across the country, so one person would work on the board, ship it to another person and they’d assemble the board and so on.” People also drove parts around, he said—whatever it took to keep the work going.

In the last year, hardware has been shipped to members in San Diego, Modesto, Camarillo, Anaheim and Mountain View in California and New York, Illinois, Wisconsin and Utah outside of the state, Kovesdy said.

Knowledge Sharing

A key piece of rocket lab, Kovesdy said, is knowledge-sharing. “A lot of rocket building is not as much a science as an art,” he said. “They are all handmade—one-offs—so we worry about losing that ability to build rockets by hand since it’s hard to put down into words.”

Weekly Zoom meetings have helped preserve—and even enhance—learning and sharing practices at rocket lab. “Everyone comes and watches the processes. Having the meetings online means we have a recording and also enables more people to attend because of how convenient it is,” Kovesdy said.

Structural Reinforcement

Rocket lab has always been a space for students to gain rocketry experience while having fun. This element is probably what has changed the most, Struhl, an astronautical engineering major at USC Viterbi said.

“Before, people would just come to the lab and hangout, and if something was going on with the rockets, they’d just walk over, look at it and help with it,” Struhl said. “Operating remotely, you can’t just catch someone in lab and say ‘let’s do this quickly before class.’”

The result, Struhl said, is more structure.

Added Kovesdy, “It’s a logistics nightmare with a million moving parts, so that has necessitated extremely detailed planning, day by day, of where every part has to go.”

Leaders in Rocketry

In the backdrop of pandemic limitations, USCRPL is continuing to innovate student rocketry. In addition to building solid rockets, which use ammonium perchlorate packed into the motor itself, USCRPL is starting to build liquid rockets, which use liquid propellant that is fed directly into the rocket, echoing industry trends—for instance at Blue Origin or SpaceX. The team hopes to test fire its liquid engine as soon as safety regulations allow.

USCRPL also has a new lab space to set up, as well as technology at the Baum Family Maker Space they are eager to use. “There are some new machines we are very excited to try out,” Kovesdy said.

Ultimately, while the team has been making it work, getting back into the lab together is critical.

Said Kovesdy: “At some point you have to put design and paper to practice. We’ve prepared a detailed safety plan and hope we can get back soon.”

Published on April 14th, 2021

Last updated on April 30th, 2021