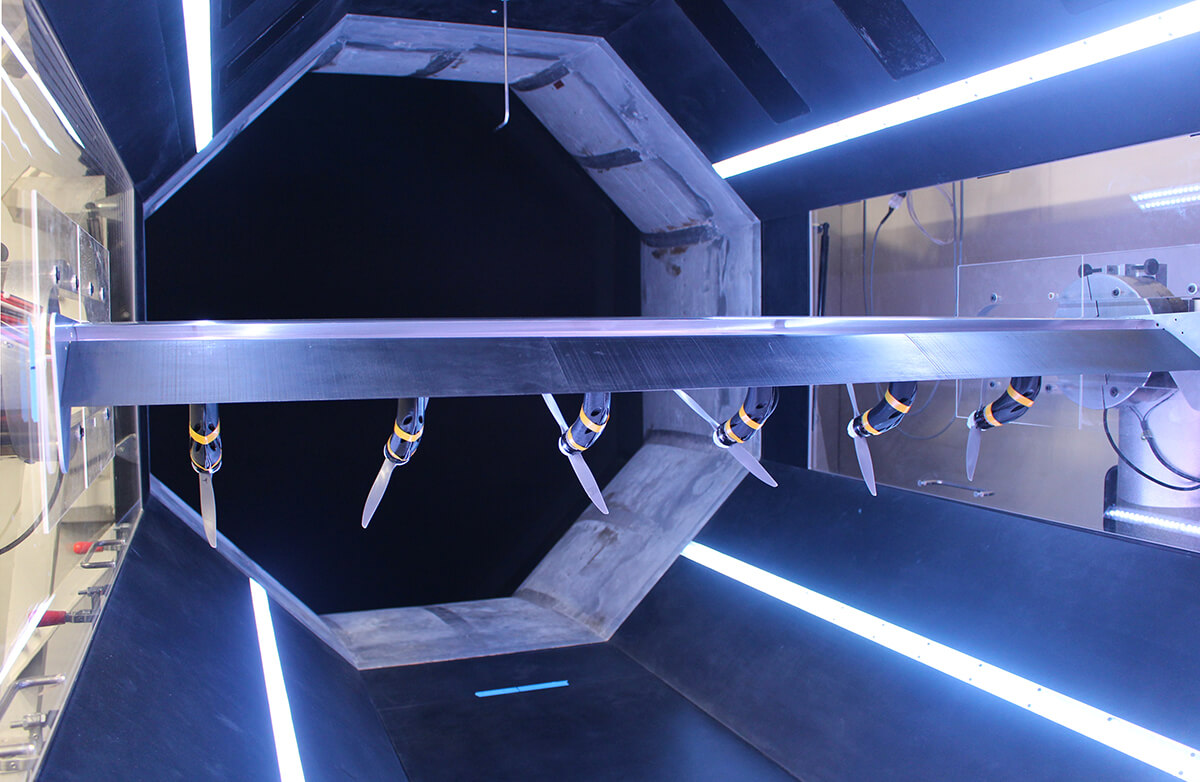

Dryden Wind Tunnel demonstration of propellers designed to drive a high lift flow for a “very short take-off” wing configuration

Delivery drones, flying taxis, zero-emissions aviation — it’s an exciting time for innovation in aerospace. Young engineers entering the industry are no longer simply tasked with refining the design of existing aircraft; they’re being challenged to reimagine the “how” and the “why” of flight.

The Department of Aerospace & Mechanical Engineering at the USC Viterbi School of Engineering has a history of expertise in experimental aerodynamics and fluid mechanics – a reputation enabled by the on-site presence of the legendary Dryden Wind Tunnel, located alongside the Blue Water Channel and other smaller apparatuses – affectionately known as the “Fabulous Fluids Facility” – housed in the Rapp Research Building.

Fabulous? Absolutely. The wind tunnel is recognized as among the best of its kind, capable of producing extremely smooth air flow at speeds from 2 to 35 meters per second (4.5 to 78 miles per hour). In other words, it exemplifies what Professor Geoffrey Spedding describes as “beautiful flow”: the minimal turbulence, textbook-level uniformity that’s ideal for experimentation and testing new flying devices.

The benefit of access to superb equipment is further enhanced by the department’s culture of exchange between researchers studying aerodynamics and hydrodynamics.

The team behind the renovation gather with Dean Yannis Yortsos: Paul Ronney, Mitul Lujar, Alejandra Uranga, Yannis Yortsos, Geoffrey Spedding, Michael Kruger

Air and water are both fluids of a kind, meaning that experiments can take place interchangeably in the wind tunnel and the water channel – scaling up and down to generate comparable results. With that ethos of collaboration already in place, and industry partners calling for ever-more inventive approaches to research, it was high time for the Fabulous Fluids Facility to receive a bit of TLC: a major renovation of the wind tunnel in addition to the refurbishment of the space as a whole.

The completion of the project was marked by a celebratory ribbon-cutting ceremony on 20 April, where the three leads of the project – Professor Spedding, Professor Alejandra Uranga, and Professor Mitul Luhar – presented highlights from major research initiatives made possible by the facility.

“New fabrication techniques and new configurations are continually driving a broad array of fascinating fluids problems, and the renovation is part of the movement towards combined computer-controlled experiments, models and simulations,” Spedding explained.

To this end, the wind tunnel has been equipped with an upgraded main drive motor and control system, as well as three swappable test sections for greater flexibility and speed of productivity. Meanwhile, the surrounding space has been reconfigured to include an efficient control room and a highly capable workshop.

The event was a celebration of the history of the facility, as well as the new era of innovation. Originally commissioned in 1918 at the National Bureau of Standards in Washington, D.C., the wind tunnel was modified in the 1930s to become the world’s finest low-turbulence tunnel, capable of detecting flow instabilities that had previously eluded measurement. Transported to Los Angeles by train in 1975, the stalwart wooden structure has been in continuous use ever since.

“The Dryden Wind Tunnel is a piece of history where many of the seminal experiments on aerodynamics were performed,” said Professor Paul Ronney, chair of AME. “Since Professor John Laufer arranged for the wind tunnel to be moved to USC, several faculty members and countless generations of students started their careers at the facility and have gone on to flourish. Today, it is still a workhorse facility where new discoveries in low-speed aerodynamics are being made, with applications to sustainable aviation, urban air transportation, drone delivery systems, and micro air vehicles for surveillance and communication.”

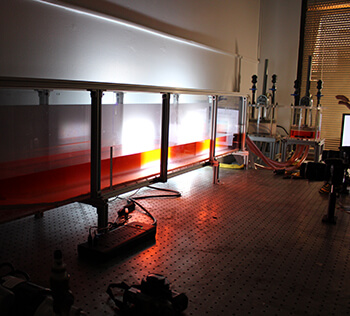

Shear layer wave flume under density contour visualization in the Blue Water Channel

The enhanced system is already allowing for advancements in research, as groups led by Uranga and Spedding pursue research into novel aircraft configuration and propulsion systems, at both a small scale (autonomous surveillance) and medium scale (very short take-off and landing) electric powered aircraft. Luhar’s research group has explored drag reduction using unprecedented 3D printed surfaces, and the water channel has also been used for research into soft robotics and flow control with new surfaces and materials.

The quality of the work taking place in the facility is as much about process as it is about results; the fluidity with which experiments can be translated to different equipment, and the potential for ideas to move between diverse minds. The renovation builds upon a history of excellence and provides the optimal conditions for future innovation – ideas that are already being incubated in environments of beautiful flow.

Fabulous Facts:

The Dryden Wind Tunnel:

- The Dryden Wind Tunnel was the first to demonstrate the existence of two-dimensional instability waves in the boundary layers that grow over surfaces such as a wing or ship’s hull.

- It was used extensively in further investigations of boundary-layer stability and transition to turbulence, generating much of the classic data now found in textbooks.

- It has also played a crucial role in verifying the performance of new inverse-design, high lift-to-drag ratio airfoils, and in finding minimum drag solutions for practical bodies – including models of platooning trucks designed to reduce fuel consumption and alleviate congestion on L.A. freeways.

- The large size and gentle contraction section, combined with the nine turbulence screens, yield turbulence levels of 0.03% or below. It is therefore perfectly suited to measuring and manipulating flow instabilities that are sensitive to small background disturbances.

- Current instrumentation includes two sensitive force balances and a particle image velocimetry system to measure flow fields.

The Blue Water Channel:

- Experiments carried out in the Blue Water Channel over the past 30 years have generated important contributions to understanding of vortex dynamics and wakes-behind-bluff bodies, as well as transitional and turbulent boundary layer flows.

- A key distinguishing characteristic of the Blue Water Channel is its large size – the test section is 7.6m long and 0.9m wide.

- This large size allows for an overlap in flow conditions (the “Reynolds number” in the jargon of fluid mechanics) with the Dryden Wind Tunnel. This means that the water channel can be used to study the aerodynamics of small-scale (bird-sized) flying objects.

- While certain aerodynamic measurements are only possible in the wind tunnel, many flow visualization experiments are much easier in the glass-walled water channel. It is also easier to manufacture porous or patterned surfaces at the scales needed for testing.

- The Blue Water Channel was the facility used to develop the technology for the Kelly Slater Wave project, and has recently been used to estimate drag on soft robotic bodies and designer-configured porous surfaces.

Published on April 28th, 2023

Last updated on April 30th, 2023