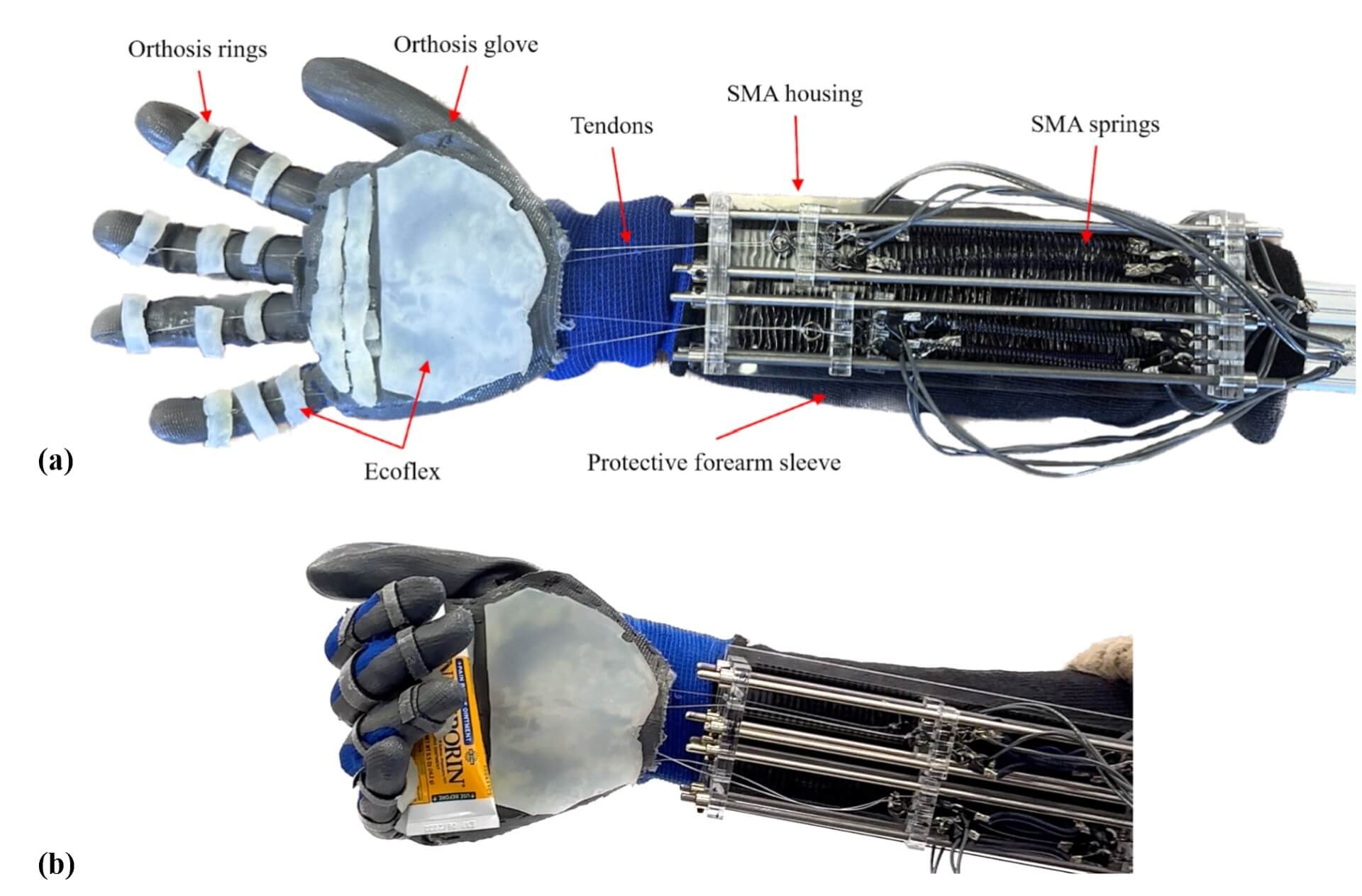

Powered hand orthosis designed to boost strength and dexterity. Senior design project developed by Olivia Acarregui, Niki Ekstrom, Bradley Martin, and John Onufer.

Carrying a heavy load of groceries, playing a game of beanbag toss, feeling your car skid as you hit the brakes. For an engineer, daily experience is a constant source of data for developing new devices and solutions.

That mentality has sparked some of the world’s most successful startups and inventions (ever wondered what inspired the idea for air conditioning?) and students at AME are trained to think like professional problem-solvers from the moment they start their undergraduate degree. The first semester of their senior year is a chance to put that blend of deep study and open-minded curiosity to the test, when they’re tasked with coming up with an idea for their capstone project. From that point on, it’s all hands on deck: forming groups of complementary skill sets, agreeing on a shared project to pursue, and working collaboratively to put a new product through design, testing and manufacture.

Papers and prototypes

The prototypes are first exhibited at the AME public showcase at the end of the fall semester. However, for many students, that’s just the first stage of developing their design. It can be irresistible to tinker, and presenting papers at conferences provides an excuse to refine their project further and spend more time in the Baum Family Maker Space.

“This year, we have several groups who have expanded their senior projects into technical papers for the AIAA (American Institute of Aeronautics and Astronautics) Student Conference, as well as other conferences such as the Society of Automotive Engineers World Congress Experience,” said Professor Yann Staelens, who specializes in teaching the practical skills of designing and building. “Like the showcase event, conferences are a great chance for students to demonstrate their hands-on experience to future employers.”

Optimized for the skies

Bradley Martin, whose group was among those selected for the AIAA Student Conference, was faced with the challenge of redeveloping his “powered hand” design into something directly relevant to aeronautics and astronautics.

The team of seniors behind the powered hand project

“The idea for the powered hand first came to me when I was coming home from grocery shopping, enjoying the convenience of carrying the bags while skateboarding,” he explained. “Then I started thinking about the people in the neighborhood who might not be strong enough to carry their groceries – for instance, the elderly and those with neurodegenerative diseases. What if we could design a device that would restore strength and dexterity in the hand?”

Martin pitched the idea to his group (Olivia Acarregui, Niki Ekstrom, John Onufer), and together they developed an orthotic exoskeleton structure that can be worn like a glove. At the press of a button, powered actuation components contract the hand through the use of special springs made from shape memory alloys – a medley of malleable metals that return to their original shape when heat is applied via an electric current. “This removes the need for a heavy motor, and that’s important because the users need the glove to be as lightweight as possible.”

When contemplating how the device could be used in space, the team considered the experience of astronauts tasked with long hours of servicing complex machinery – all the more difficult when wearing a space suit. “Imagine the resistance you feel when making a balloon animal – similarly, every time an astronaut contracts their hand, they have to overcome the internal pressure of the suit. A glove like this could really help with fatigue.”

Take aim

Another project – inspired by the favorite BBQ game of bean bag toss (cornhole) – was already ideally suited to the AIAA Student Conference. Applying an algorithm based on camera tracking, it predicts the landing spot of non-rigid falling objects to achieve the perfect catch.

“That projectile motion is known as ‘collapsed parachute descent,’ explained Benny Cohen, whose team members include Colin Duffy, Bryce Heitner and Joy Uehara. “A lot of non-rigid entities fall in that way – for instance, the SpaceX payload fairings of the reusable rockets fall with a similar trajectory of descent. That’s often very difficult to track.”

The physical build of the model was constructed with 3D printed components, and the cameras trace the movement of the falling object in a manner similar to the human eye, translating 2D images into a 3D parallax of the object’s location in space.

“Obviously, we’ve chosen a fairly simple object to track. But this approach to problem-solving can equally be applied in multiple contexts – including the contentious issue of surveillance balloons.”

Transferable skills

For seniors involved in USC Racing, the student-run team that builds, tests and races high-performance autocross racecars, the senior project is an opportunity further optimize their car design. When Jude Nejmanowski, engine lead engineer of USC Racing, recognized a gap in the market for an economically produced yaw probe, he and his team decided to create one from scratch.

“Aerodynamic yaw is the difference between a vehicle’s heading and its direction of travel,” he explained. “Yaw is significantly higher in racecars, which is a product of the tires skidding through a corner. So, it’s important for engineers to be able to measure the difference at a given time, making aerodynamic packages which work better for your car.”

The project, developed in collaboration with Alvin Ahn, Daniel Bae and Matthew Pozzi, has been selected both for the AIAA Student Conference and the Society of Automotive Engineers World Congress Experience. As Jude sees it, the yaw probe is as relevant for autocross hobbyists as it is for industry professionals, given that the sensor is up to 97% cheaper to produce than existing market solutions. That’ll be music to the ears of anyone currently building a car in their garage.

These are just a selection of the many AME senior projects heading to conferences this year. The projects are a great chance for students to align themselves with the industry they want to enter, practicing presentation skills as they pitch their ideas. It can also be a way of identifying an area of research that might lead to a master’s thesis or a Ph.D. Of course, the ultimate optimization hack is how to time-manage these projects alongside the competing demands of finals and school life. And as these students have discovered – when you’re truly doing what you love, somehow it all fits together.

Published on March 21st, 2023

Last updated on March 21st, 2023