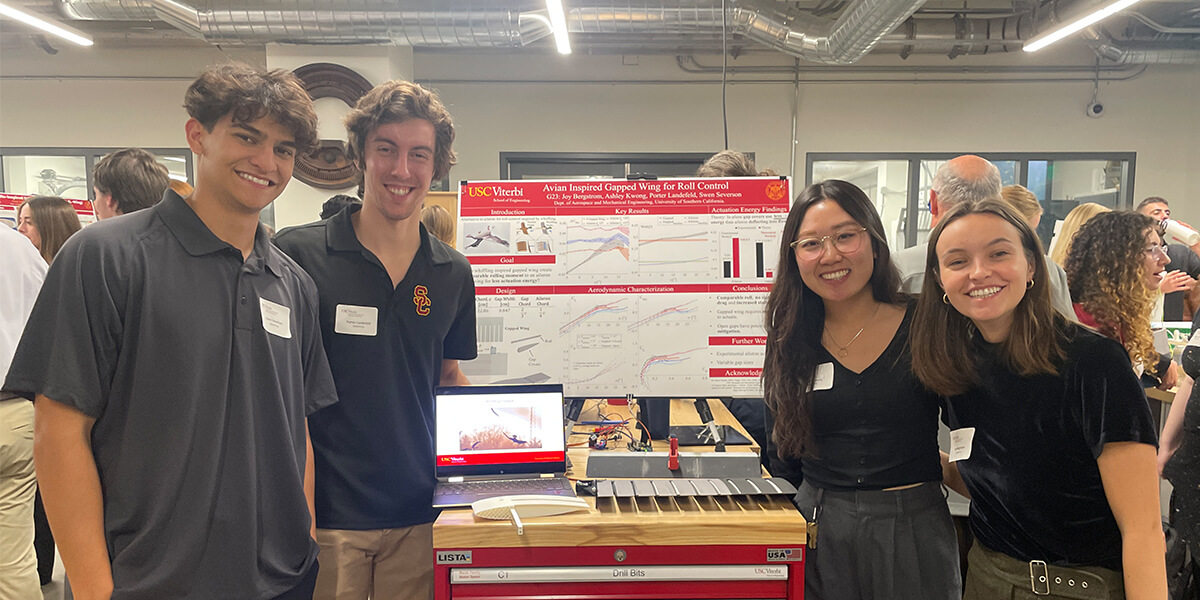

Swen Severson, Porter Landefeld, Ashley Kwong and Joy Bergstrom present their AME senior design project: avian-inspired gapped wing for roll control

For every wild new technological advancement that hits the headlines, there’s a group of engineers steadily and collaboratively working behind the scenes.

The annual AME Senior Design Showcase is a deep dive into some of the gnarliest problems being tackled by manufacturers today – problems that change every year with the rapid evolution of the tech ecosystem. It’s a sobering experience for techno-utopians (bringing sci-fi dreams back down to earth) but also an exciting opportunity to meet the bright minds who will soon be shaking up industry norms.

Here are some of the highlights – just a selection among the many ambitious and experimental projects on show.

Starting simple, aiming sky high

Efficient and cost-effective technologies for electric propulsion are a hot topic as the world enters the era of commercial space exploration. With their design for an ablative pulsed plasma thruster, seniors Thuy Pham, Brendyn Byrne, Henry Adam and Sami Haq set their goals sky high – by starting simple.

Ablative pulsed plasma thrusters are widely recognized as one of the simpler mechanisms for propelling small spacecraft systems and satellites – useful, given the immense complexity (and therefore production costs) of most electric propulsion systems.

“The benefit of these thrusters is that you’re not using that much power for the amount of thrust you’re generating,” explained Pham. “However, they aren’t as efficient as other types of electric systems. Most of the power is dissipated in unintended low-energy discharges outside of the pulsed firing cycle. As engineers, our goal is always to increase the efficiency of a system. So, we essentially analyzed the functions of a traditional ablative pulsed plasma thruster and reworked the electronics to optimize.”

After experimenting with different approaches, the team discovered that controlling the flow of electricity with a diode had the visual effect of not only increasing discharge intensity, but decreasing the frequency of discharge current oscillations. By decreasing these dissipating effects, the thruster increases its mean exit velocity. This finding is significant because it suggests the potential for a significant reduction in power required – a primary consideration of spacecraft missions – as well as increasing the performance of the thruster.

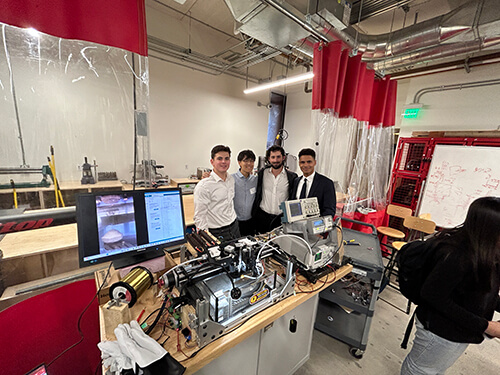

Aiden Walters, Dylan Cha, Thomas Bulow and Youssouf Keita present their AME Senior Design Project: a mechanism for desktop wire electrical discharge machining

“For me, one of the best aspects of the project is the real-world relevance – theoretically, a mechanism like this could really make a difference to the future of low-cost electric propulsion,” said Adam. “Plus, we get to work on a project we find interesting, with people who are fun to work with. It’s a win-win.”

A student-first approach to industry solutions

An added benefit of the ablative pulsed plasma thruster project is its accessibility to students – this type of reworked, comparably simply technology is ideal for students designing prototypes for space systems without relying on access to more complex electric propulsion devices.

The same mentality of accessibility motivated the design of a mechanism for desktop wire electrical discharge machining (EDM), a project produced by Aiden Walters, Dylan Cha, Thomas Bulow and Youssouf Keita.

“Student teams at Viterbi often need to manufacture metal parts for their design projects, but these machines are typically unwieldy, large scale and expensive – at least in comparison to the more efficient 3D printing devices that are primarily used for plastics,” explained Keita.

In this case, a solution geared towards for students is simultaneously a solution for industry. “If you can reduce the footprint of a metal machining mill to something that can fit on a desktop, you can fit many more of these devices within the space of a lab and dramatically increase productivity. You would be able to cut multiple parts at the same time, have more people working on projects and ultimately cut costs. Plus, it would make the logistics of shipping and installing much easier – the whole flow of manufacture would be much smoother.”

The beauty of EDM is that it doesn’t rely on force to cut metal. Whereas a typical mill would require a cutting tool harder than the material to be cut (resulting in ever more expensive parts), EDM just requires copper and an electric spark to cut any type of conductive material.

The team opted to use a very thin copper wire of 1/10,000 of an inch to maximize precision of cutting. The tricky part was how to spool the wire.

“If we’re continually extending electricity through a thin wire, the wire will eventually break down before the cutting is complete – this would mean that machining a complicated part could take hours,” said Walters. “We needed to find a way to spool the wire so that you’re always renewing the section of the wire in contact with the metal and that it’s moving consistently.”

The team’s ingenious solution was to design a system that works in the manner of a sewing machine, moving the copper wire through the metal like a thread through cloth. “The important thing is that the wire is continually spooled and pulled taut to ensure precision,” said Keita.

With this goal accomplished, the team are now looking to further boost the accessibility of the technology. “Now we’re trying to figure out how to design the spooling system so that the user can easily spool the wire. We’re determined to make metal machining as fluid and intuitive as using a 3D printer.”

One step closer to net zero aviation

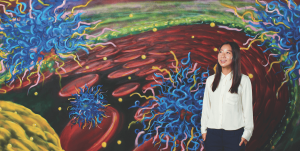

Another booth at the showcase took it back to the skies, with an avian-inspired gapped wing for roll control – an innovative control system for the new generation of electric aircraft.

The team of Joy Bergstrom, Ashley Kwong, Porter Landefeld and Swen Severson were inspired by the global drive towards net zero aviation. “Our project is applicable for electric aircraft that are highly dynamic, like drones and unmanned aerial vehicles (UAVs),” said Kwong. “The weight of the battery these aircraft can carry is very limited, so they need to save all the energy that they can.”

The team’s design of a gapped wing for roll control is intended as an alternative to ailerons – the hinged flight control surfaces that are traditionally used to control the aircraft in roll, thereby changing the direction of flight.

“Instead of using a hinge, our design features gaps in the trailing edge of the wing,” said Severson. “By having gaps that slide in and out within the same plane of the flow, the goal is to replicate the same roll moment coefficient with less energy required.”

The energy saved by optimizing the control system serves to boost the range and capabilities of the aircraft. Smaller UAVs and energy-constrained vehicles are an ideal test case for an idea that could be applied at larger scales.

“Having a more efficient control system is just one of the ways that you can save energy for electric aircraft, but the impact is profound. A design like this could open the door for electrification of aircraft overall,” said Kwong.

For the team, part of the fun of the project has been the process of trialing their designs in the wind tunnel. “It was fantastic when we witnessed our wing in action in the tunnel, seeing our idea come to life,” said Severson. “It became clear that this design could have a life beyond the lab space, and even be a game-changer for the aviation industry.

An exoskeleton for astronauts

On their journey to becoming professional problem-solvers, Viterbi engineers learn to be experts in questioning assumptions.

As AME students specializing in space applications, Kaitlyn Kumar, Manas Shah, Nicolas Gomez and Yvonne Li are well aware that the process of walking on other planets isn’t as easy and airy as it might look – for astronauts, each jump is extremely hard on the body.

The team’s exoskeleton design, FROGO, is intended to solve this issue. The name stands for “Flexible RObotic Gait Optimization” and the motion-assist mechanism is designed to enhance jump travel to make planetary navigation more efficient for astronauts.

“If you’ve ever watched videos of astronauts on the moon, you’ll see a lot of jumping and hopping,” said Kumar. “This can be very tiring – if you tire easily or don’t have full control over your movements, that could result in injury. Our solution was to create an electrically-actuated knee exoskeleton that can assist the jumping motion while adding controls, therefore making the process less taxing on the human body.”

To quantify the performance of their design here on Earth, the team is measuring the jump height increase enabled by the exoskeleton. “Typically, a jumping exoskeleton might result in a 5-8% increase in jump height,” said Kumar. “And that’s at the risk of significant stress and bruising to the body. Our solution was to create a set of lightweight parallel legs: the mechanism directs the force towards the ground, which allows for the assistance in motion without imposing excessive force on the body.”

The project is equally innovative in its optimization of controls. “We implemented various algorithms when designing the exoskeleton,” Kumar continued. “One of these factors in how much force your muscles can produce. Another algorithm is based on the expected torque (rotational force) during movement – effectively modeling the human as a robot. By following the natural curve of the body during a jump, we can minimize the torque applied to the knee.”

By refining the mechanical design and following those curves, the team was able to reduce power consumption during jumping by approximately 26%, as well as increasing the jump height by 10% – results that compare to those achieved by industry-standard tests of mechanically complex carbon fiber exoskeletons. The support and resources of the USC Dynamic Robotics and Control Laboratory were essential to the team’s success.

“Working on the project taught me that often it’s best to design simple. Just approach the problem clearly and logically, with the resources you have available. There’s no need to overcomplicate – it turns out you can do a lot for your design with not too much.”

Published on December 14th, 2023

Last updated on December 20th, 2023