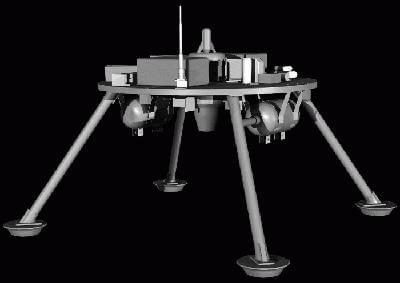

How it will look: LEAPFROG

It’s a model lunar lander, and Viterbi School astronautical engineering grads and undergrads have been jumping to get it designed and built with substantial ISI help.

The dedicated research project to create a Lunar Lander Prototype Vehicle began September 1 and proudly showed off its hardware December 4th at the 2nd Space Exploration Conference in Houston.The December 4 presentation brought the team high visibility, said Davd Barnhart, the director of the Aerospace Technology and Systems Center at the Viterbi School’s Information Sciences Institute, and leader of the project.

JANUARY UPDATE: The LEAPFROG team has successfully static- tested its engine. See video of the test at:

http:// viterbi.usc.edu/images/video/leapfrog_static_test.mov

Two students of the original team were hosted there by Boeing Corporation as part of a Future Leaders Initiative, and talked to a host of industry and government participants, including the Director of Ames Research Center and the Chief Scientist of Marshall Space Flight Center.

“As a result of the conference the LEAPFROG team is in discussion with an industry partner to potentially fly some of their real hardware on the lander for flight test verification, exactly what LEAPFROG was meant to do,” Barnhart said. LEAPFROG stands for “Lunar Entry and Approach Platform for Research on Ground.” Barnhart has been been working with Mike Gruntman, Chair of the Astronautics and Space Technology Division (ASTD) supervising an enthusiastic group of 14 budding ASTD astronautical and other department major engineers, graduate and undergraduate, in building a small, autonomously controlled hovercraft that can simulate the problems involved in setting down on the moon.

According to Barnhart, the design is inspired by a real, full- size machine used to train Apollo astronauts, the Lunar Lander Research Vehicle, a flyer that simulated (by means of a special, additional jet engine) the reduced gravity that the Lunar Module would encounter. LEAPFROG is smaller (a little more than 3 feet in diameter) and much, much cheaper (about $12,000 compared to millions for the original LLRV).

But Barnhart said it will provide “an actual flight platform &hellip to test early prototypes of key landing subsystems, through a similar profile, and in similar dust and lighting conditions that will be experienced on the moon.”

The goal is “hardware, not paper,” in the words of the project plan, with a “focus on rapid fabrication, integration and test – build a little, test a little, fly a little.”

The success so far has already attracted the attention of the aerospace community and NASA, leading to an invitation to showcase the project in Houston.

“I am amazed at the progress and scope the student team has achieved in such a short time,” said Alan Weston, from Ames Research Center, who attended the Critical Design and Integration Review, which the team held only a few weeks after coming together.

The student participation is not just assembling an existing idea. Rather, the effort involves everything from designing from scratch using off-the-shelf components to assembling and integrating a complete flight system.

The design team follows traditional spacecraft subsystem roles including system engineering (Kristina Rojdev); guidance navigation and control (Morgan Hendry); structures (Michael Rudolph and Allen Eramya); jet engine (Jason Cheng); power and harness (Lucy Hoag); communications (Omer Faghfoor), ground and flight systems (Nicole Jordan) and attitude control (Alvin Garcia, Jose Martinez and Savith Chauhan).

So far, the principle obstacles have been juggling the student team’s schedules with the demands of a fast paced flight project.

Barnhart said standout successes have included design and fabrication of the attitude control thrusters by Savith Chauhan within six weeks, a process normally taking three months; architecting, purchasing and running the Rabbit microcontroller software and PLC hardware to control the jet engine and the ACS thrusters by Omair Rahman and Cassandra Raskin; and successful test firing and characterization of the jet engine by Jason Cheng and Daniel Frolich on campus, within one week of training.

The teams’ next major step will be to execute a static hot fire test of the jet engine and the attitude control system.

This semester, the goal is just to get off the ground, but Barnhart plans to have LEAPFROG continuing to jump in coming semesters.

Team LEAPFROG: Back Row (l- r): Lucy Hoag, Nicole Jordan, Kristina Rojdev, Cassandra Raskin Front Row: Allen Eramya, Jason Cheng, Michael Rudolph, Omair Rahman, Omer Faghfoor, Morgan Hendry, Paul Guilano, David Barnhart On team but not in picture Alvin Garcia, Jose Martinez, Savith Chauhan

Published on January 22nd, 2007

Last updated on August 6th, 2021