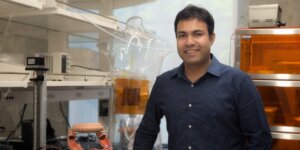

PhD students Bozhou Zhuang and Anna Arcaro are researching AI-enabled techniques for the safe storage of spent nuclear fuel.

When PhD student Bozhou Zhuang was asked by his PhD advisor to do research regarding nuclear waste, his first thought was: “Will I survive?”.

The advisor in question was Bora Gencturk, professor of Civil and Environmental Engineering and the director of the USC Structures and Materials Research Laboratory (SMRL). As a specialist in the long-term resilience of material infrastructure he is well aware that – if safety protocols are followed – there is a one-in-a-billion probability that stored radioactive waste would be leaked.

PhD students Bozhou Zhuang and Anna Arcaro in front of a research mock-up of a nuclear fuel canister

In fact, nuclear energy is one of the cleanest, most secure and efficient energy sources available. A single uranium fuel pellet as small as a fingertip can produce as much energy as 17,000 cubic feet of gas fuel, 1,800 pounds of fossil fuel, or 150 gallons of oil – add to that, the benefit of zero carbon emissions. There are currently 440 commercial nuclear power plants in operation, providing 20% of global electricity.

So how did nuclear energy get such a bad rap? Each year, over 10,000 tons of “spent” nuclear fuel are produced worldwide, requiring a long-term storage solution until researchers discover a way to neutralize or recycle the toxic waste. These days, excess spent nuclear fuel is contained within dry storage canisters constructed of stainless steel – an alternate solution to the waste pools within nuclear facilities (if you’re imagining something like a glowing green swimming pool, you’re not far wrong).

However, the current canister solution isn’t yet optimal. At a minimum, these containers need to store the spent fuel for 50-100 years, buying us time as we pursue the secret of how to best manage this effective – yet lethal – resource.

The trouble is, any number of risky scenarios might happen in the intervening years – an area of hazards research that has progressed rapidly in recent years, thanks partly to Gencturk and graduate students at SMRL. The team has raised awareness of the potential consequences of aging and environmental degradation on nuclear storage canisters, especially in the context of extreme events such as earthquakes. They’re now strategizing ways of safely testing for damage, with the goal of ultimately improving the material performance of nuclear storage solutions.

“Having identified the contingent risks, we’re now facing the question of how best to inspect the canisters for internal corrosion or cracking – for instance, identifying whether it’s safe to transport them to alternative locations,” explained Gencturk “Opening the sealed canisters is an expensive, time-consuming and potentially dangerous process, so our research group has been investigating more efficient ways to test for durability.”

PhD students Zhuang and his labmate Anna Arcaro are researching a series of innovative AI-enabled techniques for routine inspection and maintenance of the canisters, supported by funding from the U.S. Department of Energy and the Nuclear Regulatory Commission. The results have been published in esteemed journals including Engineering Applications of Artificial Intelligence, Measurement, and Mechanical Systems and Signal Processing – each publication a significant milestone testifying to the urgency of this area of research. If the team’s proposed strategies become part of nuclear energy protocol, they may resolve a challenge that has been holding the industry back for over half a century.

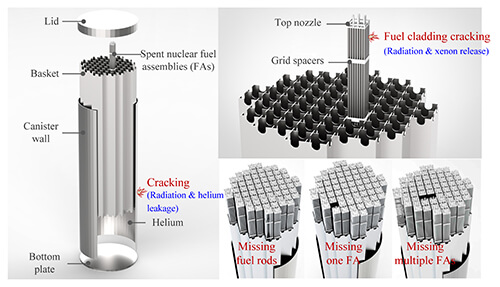

Potential internal anamolies of spent nuclear fuel canisters in long-term storage

“Just as you might visit your doctor for a regular health check, we need to take a proactive approach to monitoring nuclear infrastructure – it’s essential for the protection of our environment and the global population,” said Zhuang.

And just as the medical profession is on the brink of a revolution in AI-enabled personalized health tracking, the same may be true of the health of nuclear waste storage systems.

“Our goal is to develop experimental methods that allow us to conduct internal checks while avoiding the risk of radiation involved in opening the canister,” Zhuang explained. “In our lab, I mounted ultrasonic transducers to the exterior of a mock-up canister, and conducted experiments to evaluate the internal gas property. If impurities are revealed, this provides a clue to the presence of cracking or other types of degradation. The collected data are then processed into algorithms to learn the damage patterns.”

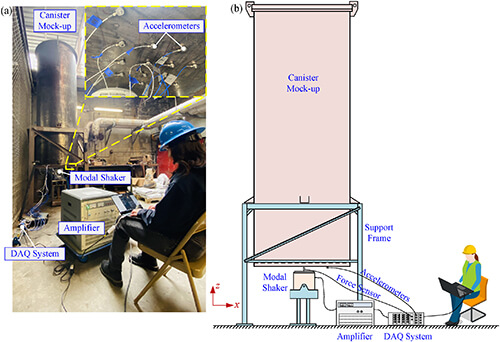

Meanwhile, Arcaro’s research involves model tests and acceleration sensors, applying machine learning models developed with the project’s co-PI, Roger Ghanem, Tryon Chair in Stochastic Methods and Simulation. “Instead of applying techniques of ultrasonic testing, I’ve been conducting experimental dynamics measurements on the canisters, collecting data that feed into the various machine learning models we’re testing,” said Arcaro. “Currently, I’m using a convolutional neural network that identifies the severity of the damage and pinpoints its location within the canister.”

For Zhuang and Arcaro, one of the most satisfying aspects of working in this area of study is the immediate applicability of their discoveries.

“This isn’t just a niche scientific method that’s fated to remain within the context of academia,” said Arcaro. “We can actually implement our methods to real canisters that are currently being readied for transportation.”

Dynamic modal test to detect missing nuclear fuel assemblies on canister mock-up

The process has called for creativity as much as procedural knowledge. It can be easy to idealize the efficiency of AI technology; after all, the accuracy of the damage-testing algorithms advances exponentially with every new influx of data. However, the material constraints of the canisters raise real challenges – such as the problem of how to avoid energy dissipation when transmitting ultrasonic signals between exterior and interior, or how to solve the puzzle of scaling between lab models and full-size canisters in industry contexts.

Working back and forth between machine learning strategies and test manipulation is an ongoing process that continues to generate potentially pioneering results. “It’s exciting that our inspection methods can help the nuclear industry to make better judgments, decisions that will prove crucial for securing a safer world,” said Zhaung.

Meanwhile, the team are hyper-aware that the clock is ticking – finding a solution to safe nuclear storage is a race against time, as canisters undergo the accumulative effects of material aging.

Published on April 4th, 2024

Last updated on April 4th, 2024