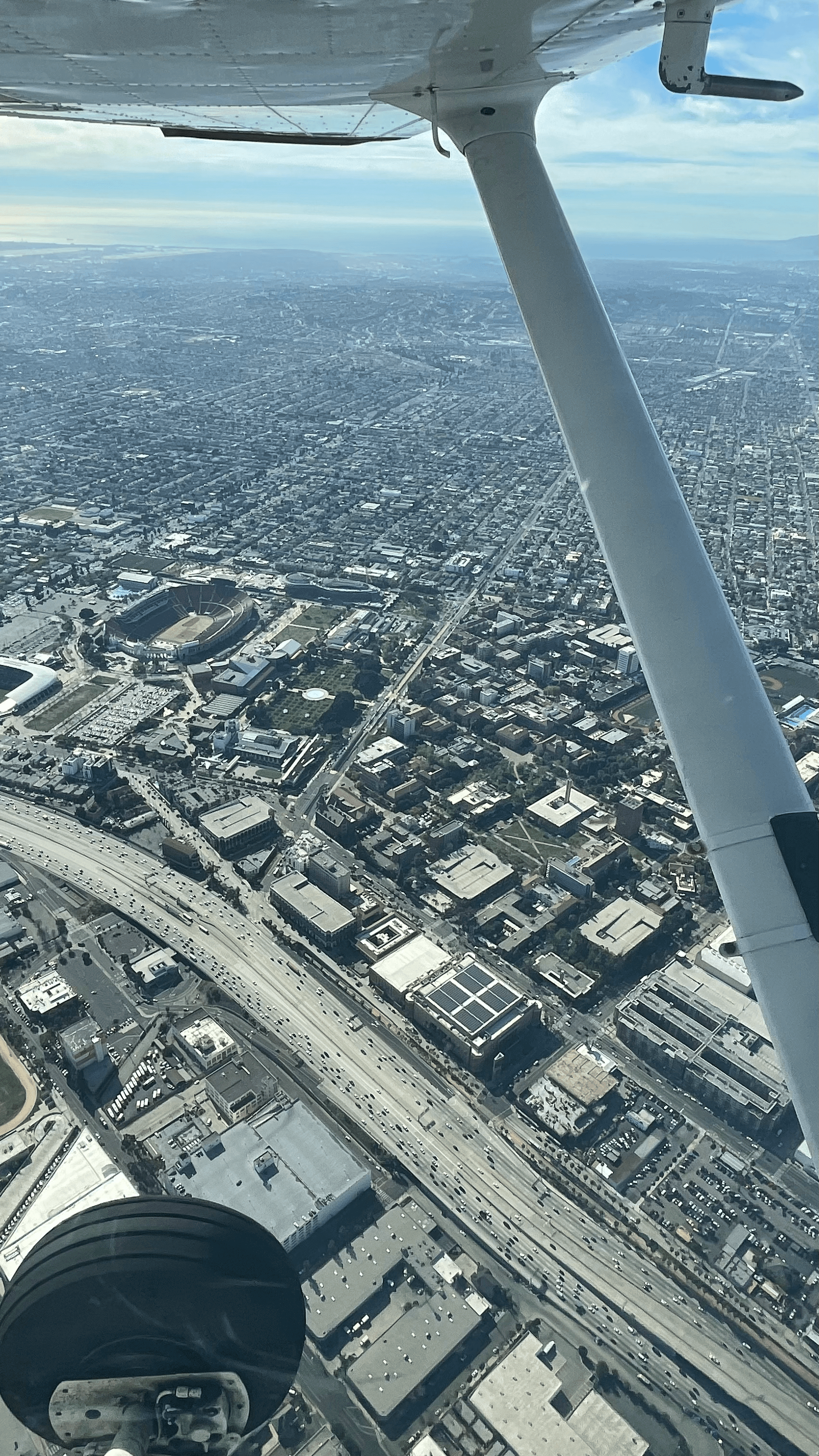

Rishi Malhan has a private piloting license he uses to explore Southern California’s skies. PHOTO/RISHI MALHAN.

For many people, the idea of flying is uncomfortable. Leaving the ground is not just a feat of human innovation that defies gravity, but also logic. Still growing up in India, Rishi Malhan obsessed over rockets and airplanes. From their mechanics to their design, he marveled at how they were developed, at the innovations that made them go further, faster into the atmosphere. But he never imagined he’d one day fly one of them.

Over the course of the pandemic, he dedicated himself for a year to earning his private pilot’s license. In addition to learning discipline and patience, he said he had to overcome the trepidation coupled with the unknowns of flight. Once he did, he learned more about who he was and gained confidence in his ability to grapple with uncertainty.

“Once you overcome the fear, you become united with the aircraft,” Malhan said. “You conquer it, you have more control over it, you start planning and anticipating … and all the knowledge gained from studying aerodynamics, you see it all happening right there,” he said.

A view from the skies. PHOTO/RISHI MALHAN.

And indeed, he’s been able to see it and experience it all – a journey that began as a child watching aerospace documentaries on television. Aspiring to be a mechanical engineer and businessman like his father and with the support and encouragement of his mother, he first moved to Los Angeles in 2016, imbued with a desire to be at the apex of where technology, industry, and knowledge were advancing and merging.

Initially, as a master’s student at USC Viterbi School of Engineering, he came to discover new hobbies and interests within the field, particularly robotics — which he was introduced to via coursework with Professor Satyandra K. Gupta in the Department of Aerospace and Mechanical Engineering.

“It [robotics] involved mechanical engineering and computer science,” he said. “I had studied both components in my undergrad and was looking for a field which could give me hands-on hardware experience and deepen my understanding of its integration with software.”

This interest naturally brought Malhan to the USC Viterbi Center for Advanced Manufacturing, which he said began with a startup-like atmosphere, where a lot had to be built from scratch. “We were procuring equipment and building the robotics lab … USC gave us permission to experiment with different machines and order what we wanted was necessary,” he said. “So it was very much like building a company, which was an amazing experience. I don’t know any other school that has such a huge robotics facility or would have given to so much responsibility to a new grad student. I really appreciate USC for that.”

Like with any “startup,” Malhan, had to learn quickly how to operate with limitations, including limited budgets and space, and also how to make decisions early on that would have long-term impacts.

“Even though most of our research at the time [2017] was based on smaller robots, we still considered bigger robots in our purchasing, because we knew at some point, we’d get into metal 3D printing, which would require the bigger components to execute.”

Working alongside Alec Kanyuck, who came to manage operations at CAM, Malhan said one of the most critical components of success was being led by Professor Gupta’s expert knowledge and insights not just into academic elements of the field, but into industry trends.

“I think that is one of the most important factors driving USC’s strength: the expertise of the professors. They are just amazing. They know what the industry wants and they’re so well-connected to the industry, they bring it in research form to the university. That information is then dispersed to students, like myself, and we try to reverse engineer products that address these needs,” Malhan said.

Heavy Metal

While they say leaders aren’t supposed to play favorites, Malhan does have a favorite tool he likes to experiment with.

“I was most excited about the metal 3D printing machine,” he said. “It is a gigantic machine occupying an entire room [at CAM]. The sheer cost of operating it and the parts it prints are awe-inspiring.”

But in terms of research, Malhan is partial to the robots. His research focuses primarily on motion planning. “Most of the robots now are used for repetitive tasks. The humans teach the robots how to operate, but the robots aren’t really making decisions on their own. But what if you want them to?” he said. “You have to plan the motion trajectory, so the robot understands how to meet your constraints, etc.”

The field of motion planning involves using machine learning coupled with different search and optimization algorithms, Malhan said. While a lot of researchers have done work in this area, Malhan said what interested him further was projects involving robots under constraints.

“For example, multiple robots manipulating deformable materials are constrained with physics of the material and each other’s motions. Similarly, for tools interacting with a part to perform specific operations or tracing paths over the geometry like in robotic sanding, painting, additive manufacturing. You have to stay in a certain area and follow a specific path, so motion planning under constraints becomes a very challenging problem,” he said.

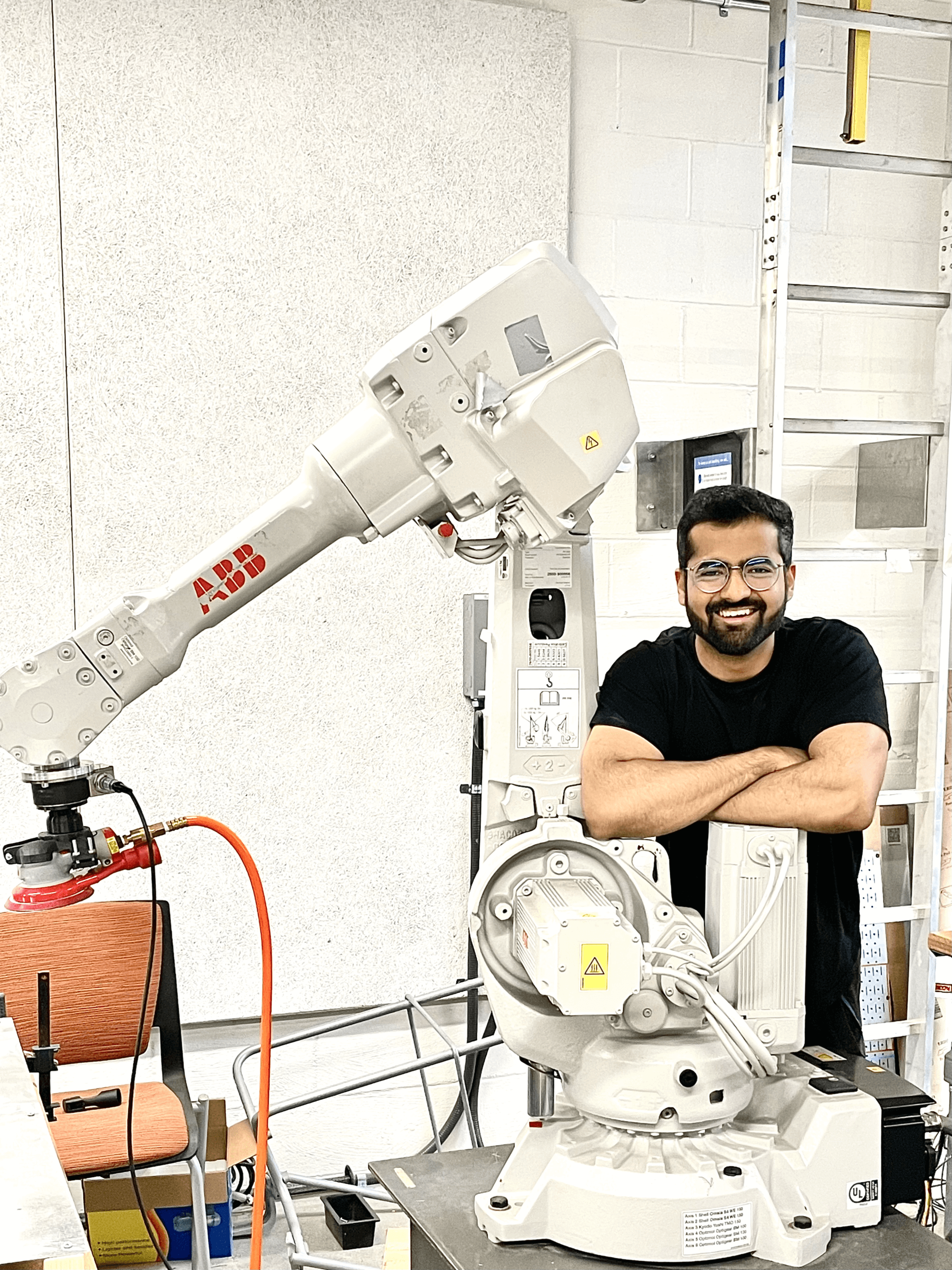

PHOTO/RISHI MALHAN.

Practically, Malhan has applied such skills with Berkshire Grey, a company that supports e-commerce by using robots in order fulfillment. “So if you ordered four or five items, those items will come from the warehouse and conveyors and then this robot will take those items and put them in your box. It has to follow a certain path and constraints are not just spatial, but you have dynamic constraints – if the robot’s moving too fast, it can drop your item and damage it.”

At the same time, Malhan said such use of robots is just the beginning. “In the next two or three years, we’re looking at even more AI involvement in robotics,” he said. “This will need a human component. AI systems are well versed with interpolations but bad at extrapolating, so humans will need to guide the AI.”

Patent Pending

One of the key motion planning applications Malhan has worked on is a composite sheet layup technology for which he has submitted a patent application. Composites are used primarily in aircrafts now, he said, to make them lighter.

“But all of that manufacturing is done by humans, and humans face consistency issues,” he said. “Robots, by default, are very consistent.”

The patent focuses largely on the software regarding motion planning, which helps robots navigate constraints using computer vision, but also a bit on the hardware required, for example grippers and conforming end-effectors that should be used for the robots, Malhan said.

Trojan in the Sky

Following graduation, Malhan is returning to work at Berkshire Grey, which he hopes will not only help him further hone his technical expertise, but also continue exposing him to different departments like marketing, finance and operations. Long-term, he hopes to build his own company that focuses on robotics in aviation.

“Aviation is a very conservative market, because of safety issues,” he said. “But I imagine in the next five to six years, the FAA will start opening up to AI, and that’s where I want to capture the market. I know that robotics is the answer to the next big problem in aviation — though I don’t yet know what that will be.”

A lot of times, our journeys come full circle, and for Malhan, his childhood love of aerospace, from jets to rockets, led him to a beloved new hobby in adulthood. He visited aircraft museums and studied different types of aircrafts whenever he could. But it wasn’t until one of his friends revealed he had a pilot license that Malhan considered learning to fly.

Malhan learned a lot about himself during the strict and rigorous training he endured. “You have to be disciplined and patient. You have to take the time to make good decisions and be more self-aware about what you can handle and what you cannot.”

“Being in command of so much all at once is very exciting.”

Follow Rishi Malhan’s adventures in the sky on Instagram @trojaninthesky.

Published on May 9th, 2022

Last updated on May 10th, 2022